The valve train consists of different parts such as valves, rocker arms, push-rods, lifters, and camshaft. The overall structure balances the air/fuel mixture ratio entering the combustion engine. Whenever an issue happens in the valve train or any of these components, you may hear valve train noises. The noise can be a clicking or clattering sound.

Well, whatever the sound seems like, there are a few fixes that you can try and troubleshoot the valve train noise problem.

The most common reasons are the clearance issue, the hydraulic lifter problem, and the worn rocker arm. Let’s get to know how you can solve each of them one by one.

The valves open and close as the engine spins. The frequency here remains in a way that the valve opens and closes every two times your engine spins around. This movement of valves happens very quickly, and they cover a very short distance.

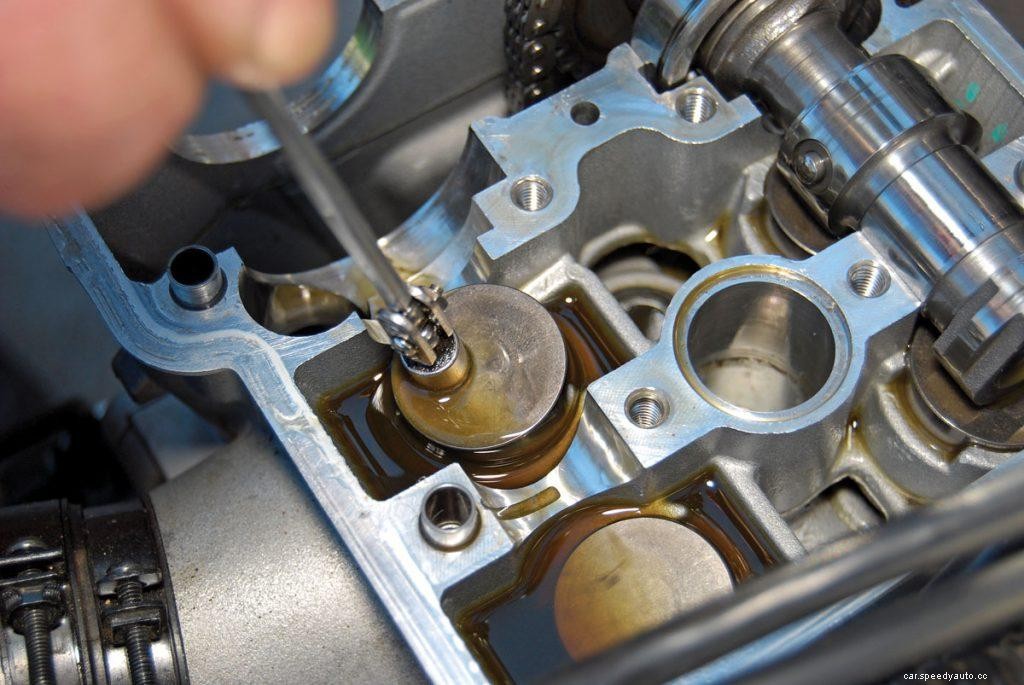

These distances are supported by adjusters, and with time as the parts wear off, the distances can increase. This overall increases the clearance, and you hear a ticking sound. This is one of the common valve train noises that you can overcome by adjusting the rocker arms or installing the new shims.

In the push-rod style engine that comes with solid lifters, these lifters should be clean. Lifters with oil deposits or any dirt can cause the engine to make sounds.

READ MORE:

The hydraulic lifter is another component of the valve train unit. When the lifter is worn or fails to perform the operation, it causes the clattering sound. However, you can always check other parts like rocker arms, pushrods, springs before going with the lifter. If all these parts seem to work fine, chances are the problem is with the lifters.

Make sure you check the following prior to performing a lifter check:

If you hear a rattling noise while starting the engine, it may be due to a worn rocker arm. Though it is rare, you can have a check on it if it has been long enough. A faulty rocker arm does not cause any harm to the engine; particularly, it causes the engine to make noise. The most common cause of a worm rocker arm is the poor lubrication system.

Here is how you can identify the problem with the rocker arm:

Use the mechanic’s stethoscope or rubber hose and check for the noisy rocker arm just as the previous step.

Check the rocker arm for any rough spots where it meets the valve as an indication of the problem.

If you can encounter any of these problems, it is a sign that there is a problem with the rocker arm. Improving the lubrication can prevent the rocker arm from getting damaged any further.

Note: Sometimes, the dirty oil can make the valve train noise. Try replacing the oil along with the filter and see if the issue gets solved.

Another time it may be because of a valve spring that needs to be refaced. Try changing the valve spring with a wrench, and if this solves the issue, you need to work with the spring. Reading the maintenance tips once in a while is a great way to keep up with the possible automotive issues and how to solve them.

If you are someone who tends to do DIY whenever an issue happens with your car, you can easily locate these problems. Otherwise, it is always wise to call your mechanic and let him have an analysis of the possible reasons for valve train noises.