If you’re looking for an article on how to look buff while driving, then go peep some clips of Vin Diesel flexing behind the wheel. However, if you are in search of some automotive detailing advice, you are in the right place.

For whatever reason, automotive clear coat polishing scares the ever-loving shit out of amateur auto detailing enthusiasts. Even the lighter, “buffing” side of the process can seem intimidating to some, when it really shouldn’t be.

In the automotive arena, the term “buffing” is often used interchangeably with the word “polishing.” However, the latter of the two tends to involve the removal of a paint protection product or damaged clear coat. Whereas the buffing process is more about whisking away polishing compound residue, and eliminating things like swirl marks and surface haze.

But buffing goes well beyond adding a spot of shine to a paint job or a chrome bumper. There are multiple techniques that can be used to accomplish the polishing process, each with their own form of implementation and outcome.

So let’s brush-up on our surface polishing fundamentals, reexamine which areas of a vehicle benefit the greatest from buffing, and note the sections that should be avoided. We’ll also go over what tools will yield the greatest results, along with a few pro tips to help turn that faded paint into a rich, glossy visual experience.

Buffing can be used to describe any number of surface polishing procedures. As a core second step in both the repair and surface protection processes, buffing plays a vital role in the daily routine of every auto body shop.

But while buffing remains synonymous with shiny surfaces, the procedure can accomplish other things, such as:

Either way, buffing is often the final step in the paint care/repair process, and is generally far milder of a procedure than say, paint correction or automotive surface claying.

While images of hot rod guys scrubbing their “lead-sleds” with microfiber mitts may come to mind when the word “buffing” is uttered, the process itself is not nearly as glamorous as one might think. Automotive buffing is typically implemented when repair and replacement procedures are in order, with the following two scenarios being the most commonplace.

The repair of automotive paint requires a multitude of labor intensive steps, with polishing and buffing being two of the more notable techniques. Polishing is the more hardcore of the two methods, as it revolves around applying a series of polishing/cutting compounds to a painted surface with a power tool and a surfacing wheel. This allows the gradual removal of any paint or clear coat damage to occur, without damaging the underlying basecoats.

Once polishing is complete, buffing begins, where a clean towel or pad are used to remove any lingering polishing/cutting compound. This not only cleans the freshly polished area in preparation for a paint or clear coat application, but it also helps expose any damage that may have been missed during the polishing stage.

Removing and repairing surface scratches, oxidation, or any number of other paint related damage from a vehicle’s surface is just part of the process. In order to insure that this damage does not occur again, the application of a paint protection product must be implemented.

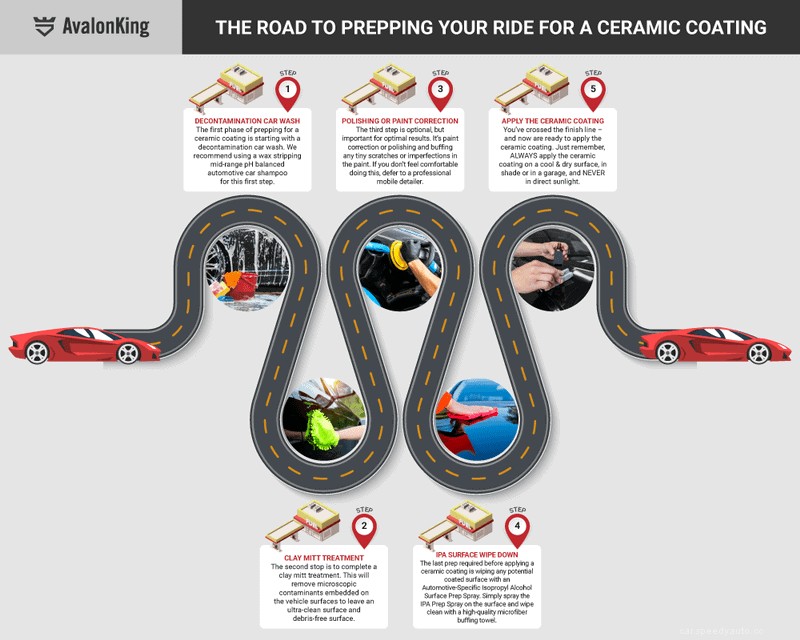

A fresh clear coat will only get you so far, which is why many car owners and professional auto detailers apply a surface protection product like ceramic coating to the vehicle after paint correction repairs are complete. Buffing is not only utilized in between correction and protection, but during the ceramic coating application procedure itself, and for damn good reason.

When a surface protectant like a ceramic coating is applied to a painted surface, a massive amount of the product either bonds or embeds itself into whatever it is protecting. Whatever does not adhere to the surface becomes residual waste, and must be removed, which is precisely where the buffing phase comes into play.

But while rubbing a surface with a clean microfiber cloth may not sound all that difficult, there is a lot of room for error in the buffing stage. Remove the protectant too soon, and it will not form a solid bond/embed correctly, thus leading to thin coverage and potential product failure.

Buff a ceramic coating entirely too late, and all of that residual media that’s been sitting on the surface will solidify atop the coating. This results in what is commonly known as “streaking,” which unlike that drunk guy running across the football field, will not inspire a hearty bought of laughter.

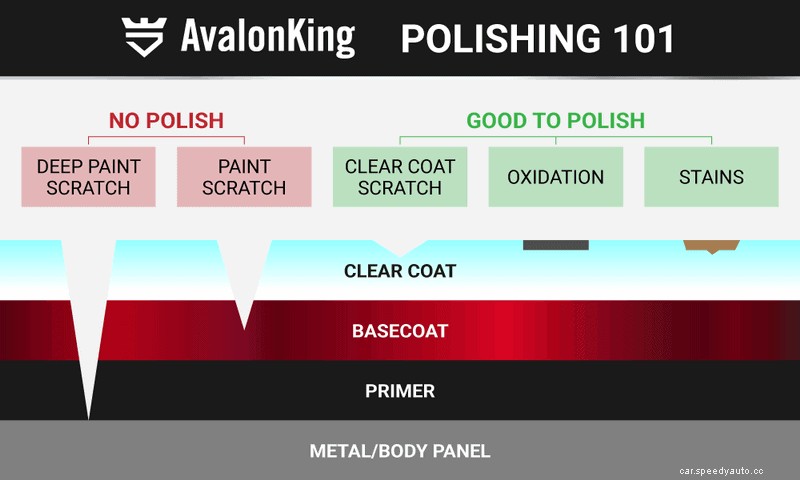

Since the act of polishing essentially involves cutting into the automotive clear coat, knowing your limitations is crucial. Certain types of paint damage, like the three listed on the right side of the graph above, are all embedded within the clear coat itself. Whereas everything on the left runs quite a bit deeper, penetrating paint, primer, and even bare metal.

If the damage is too deep, you can forget the DIY buffing and paint correction polishing procedures, because a professional repair must be implemented at that point. Sanding down to the root of the damage is no simple task, as it typically requires re-applying primer, paint, clear coat, and even body filler. This is often accompanied by lengthy rounds of color sanding, before a final polish and buffing can commence.

On the upside, if you’ve got the kind of clear coat damage that belongs on the right side of our gloriously illustrated infographic, then there are a few ways you can buff your blues away.

There’s something to be said for the old reliable elbow-grease-and-a-beer approach. While modern technology has brought with it far speedier polishing and buffing techniques, there are plenty of purists who still swear by the hand polishing approach. Despite its obvious physical and time requirements, hand buffing a vehicle does have its merits, with control and attention to detail being the top two perks.

So if you want to take it easy, and start-out with the hand polishing method, you’ll the following supplies:

On the more extreme end, veteran detailers and advanced DIY minds tend to recommend the use of electric polishers, as they provide a far more efficient experience. This method utilizes many of the same core supplies as listed above (polishing pads, cutting compounds, and buffing pads), and affixes them to an electric power tool. The results may be the same, but the time spent is far less significant.

There are three types of buffing products: Pads, towels, and cloths. All three products come constructed from either a foam, cotton, or microfiber material.

While foam applicators are generally reserved for applying things like cutting compounds and wax to vehicle surfaces, cotton and microfiber buffing products can be used for either application or removal.

Buffing Pads: A buffing pad is used when either a hand-held or electric buffing wheel is being implemented, and bonds to the face of the disc or wheel via Velcro or straps. Buffing pads come in foam, cotton, and microfiber form.

Buffing Towels: Buffing towels are a handheld product that tend to be narrow in diameter, but quite long in length. Made almost exclusively from microfiber, buffing towels are a rockstar when it comes to removing paint protection products and cutting compounds alike. A clean microfiber cloth of this degree not only reduces scratching while lifting stubborn residue, but its considerable length will make buffing corners a breeze.

Buffing Cloth: When placed next to the mighty buffing towel, buffing cloths appear quite inferior option. But don’t let these little squares fool you. They are ideal for buffing hard to reach areas where a larger towel will be too unwieldy, and are the perfect solution for anyone in search of a straightforward buffing solution.

Buffing 101 lesson complete, it is now time to review some of the more basic questions about buffing that we receive on a routine basis.

People ask if they can skip the buffing stage. We tell them that this is a great idea, especially if they like the look of crappy clear coat and unattractive nano ceramic coating streaking.

These same individuals want to know if they have to buff with microfiber, to which we respond “NOPE.” While microfiber certainly has its perks, there are plenty of foam and cotton buffing products that also work extremely well. So we tell them to do a little research, read a few reviews, and when in doubt, always ask a pro for advice.

Finally, and perhaps most importantly, we advise every DIY enthusiast to take their time and inspect their work often. Buffing is intended to clean-up a clear coat and add shine, NOT eat into layers of paint protection. It’s the aftershave and lotion of the automotive world, and when done correctly, it can spell the difference between a beautiful exterior and a seriously screwed-up surface.