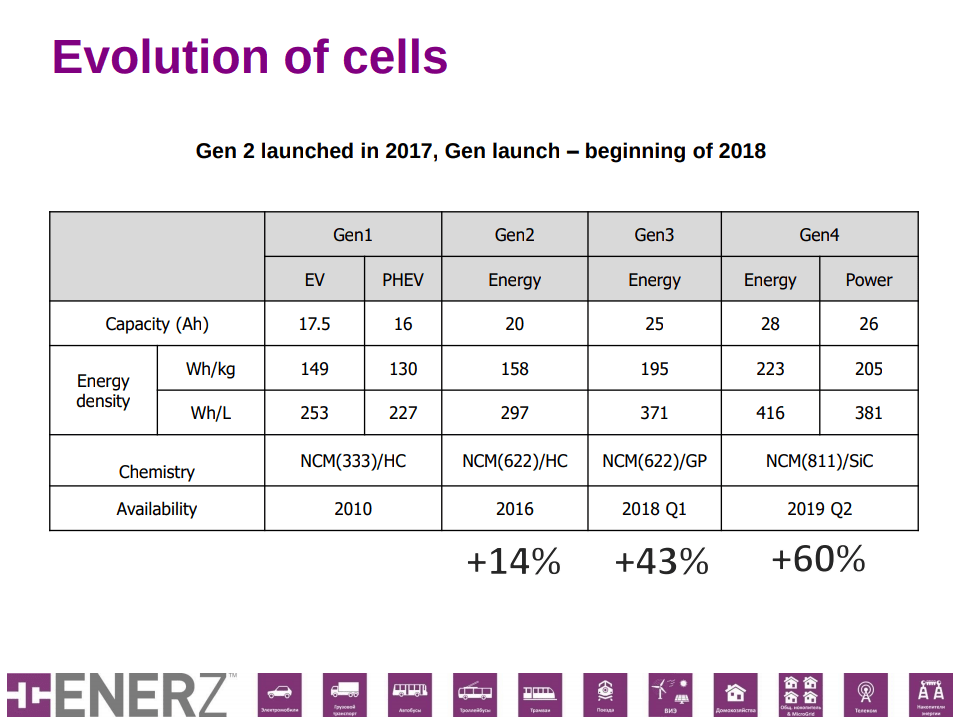

NCM battery cells developed by ENERZ have been used by heavy-duty electric vehicles (mostly buses) for years. They are characterized by having high power density and long cycle life.

Recently, ENERZ increased the energy density of their NCM 622 cells by improving the anodes, replacing hard carbon (HC) with graphite (GP). This allowed them to gain more energy density at the expense of a little reduction of cycle life and power density. Remember that a battery cell is always designed with a compromise between cycle life, stability/safety, cost, power and energy density. You can’t have the best of every world in one package.

Anyway, what’s interesting is the introduction of new battery cells with a NCM 811 cathode and a silicon/carbon anode next year. The less we depend on cobalt limited supply, the better.

ENERZ battery cell evolution roadmap

The energy density of the future NCM 811 battery cell from ENERZ is far from being impressive, but achieving high energy density was never the main objective of this battery cell maker, however low cost, high cycle life and power density is.

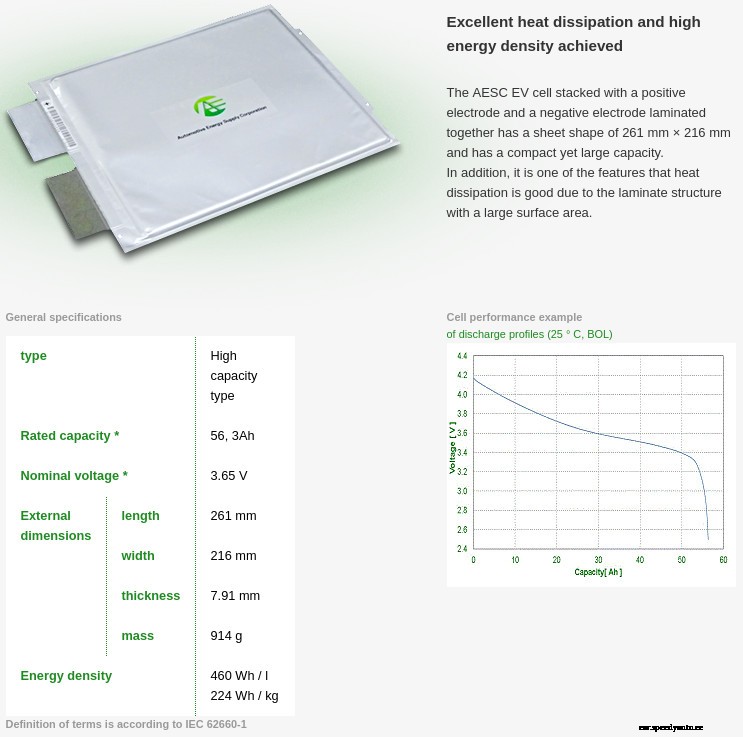

As you can see below, the NCM 622 battery cell from AESC has higher energy density, because the anode has higher content of silicon. While we usually focus on the cathodes (NCM, NCA, LTO, LCO, etc), anodes are important too. To increase energy density we can increase the nickel content of the cathodes and/or the silicon content of the anodes, but doing this while keeping the battery cell structurally safe is the hard part. Ceramic coating is one way of achieving this, but not every cell maker knows how to do it properly. In this field, SK Innovation is leader.

AESC new battery cell specs

To sum up, ENERZ battery cells aren’t very impressive, but the more battery cell makers reduce the use of cobalt, the better.