It’s virtually inevitable: over the course of months and years, rust will begin to form on your car truck or crossover. Left unchecked, it’ll spread, expand, and eventually ruin its finish, structural integrity and more.

Rust can form virtually anywhere: in obvious locations on the painted surface of your vehicle, deep beneath its floor, within its body panels, or even completely hidden from sight behind plastic trim and weather-stripping. When rust begins forming, it’s hard to stop and very invasive.

Thankfully, numerous products are available to help slow or stop the formation of rust in and on your vehicle. So are several accessories that may help protect your vehicle and prevent rust from forming in the first place. Read on for the scoop about rust-protection for whatever you drive and remember: not all rust protection products are created equal.

Rust Converter Ultra is a highly rated, affordable, and easy-to-use solution to existing automotive rust problems. Ideal to arrest existing rust or for use to repair and seal frame rails, floor pans, and body panels on project vehicles, this surface conditioner turns rust into a dark, polymeric coating via a chemical reaction.

To use it, simply clean existing rust scale from the area you want to treat, leaving as clean and debris-free a surface as possible. Then, apply the product with a brush or roller. Rust is neutralized and transformed into a dark coating. Once set, the coating acts as a primer, and can be painted for added protection.

The one-gallon jug is ideal for larger projects, and many users report that a single jug is sufficient to coat the entire frame of a pickup truck. Rust Converter Ultra can also be used on metal railings, outdoor furniture, and more. It’s cost-effective, durable, and easy to use.

CRC White Lithium Grease Spray is an ideal product to keep in your garage or toolbox to help prevent rust and lubricate hinges, latches, and other similar components on your car, truck or crossover. An aerosol can contains high-purity lithium-based lubricants and oxidation inhibitors, and a needle-tip enables precise application.

This type of rust inhibitor is commonly used on a regular basis to seal, lubricate and protect trunk and tailgate release latches, gears, tracks, power window slider components, throttle cables, rust-prone suspension mounting points, sunroof assemblies, and more.

Typically used for spot application, lithium grease is somewhat costly per unit, but the benefits are numerous: the product has a buttery, paste-like texture and is designed to stay in place without dripping or running. A waterproof, corrosion-protecting seal is left behind, and the white color makes it easy to see where it’s been applied. For strategic spot lubrication and rust prevention, White Lithium Grease Spray is a go-to.

User reviews commonly praise the product’s viscosity — which is thick enough to stay in place without worry, but also thin enough to absorb into smaller gaps.

From the makers of the world’s most famous rust-penetrating lubricant comes WD-40 Specialist Long Term Corrosion Inhibitor. The makers of WD-40 know a thing or two about dealing with rust and this product features a special formulation variant to help keep that rust from forming or spreading.

Designed to coat metal parts with lubrication and rust prevention, it works for up to 2 years when used indoors, and up to 1 year when used outside. The special formula clings to metal and seals out moisture and air—which are two of the ingredients needed for rust to form.

A precision straw applicator is included to minimize waste and overspray, and the liquid won’t dry over time or run. This special formulation of WD-40 is ideal for spot application, or for use on more wide-spread areas pre-emptively, to prevent rust from forming.

From one of the world’s most recognized brands in automotive paint comes the Exact-Match Scratch Fix All-in-1 Touch-Up Paint pen. This handy product from Dupli-Color is a great investment to purchase alongside virtually any new or used vehicle, and features a small tube of touch-up paint that’s carefully created to exactly match the factory finish of your machine.

One of the best ways to prevent rust on the finish of your car is to stop it from forming in the first place. Since scratches and chips in your vehicle’s paint expose the bare metal beneath and cause rust to form quickly, protecting and re-sealing the paint as soon as possible is vital for a long-lasting finish and higher resale value. The Exact-Match Scratch Fix includes everything you need to professionally repair minor paint damage in minutes, including an abrasive tip for proper surface preparation, a pen-tip applicator for small scratches, a brush-end for larger chips, and a clear-coat to seal and protect the touched-up surface with a factory-precise finish.

This product isn’t a rust inhibitor per se, though it’s timely use is arguably your single best defense against unsightly surface rust.

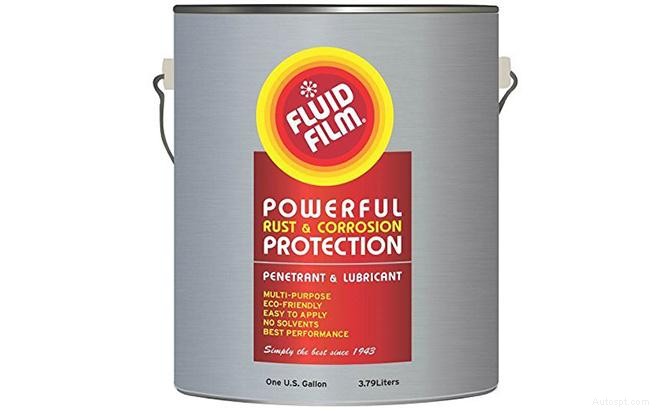

For big and highly involved rust-protection jobs, look no further than Fluid Film Protectant and Lubricant. Available in value-sized one-gallon cans, this highly rated product is perfect for the DIY enthusiast with a big rust-protection job to tackle. For best results, you may wish to use an air-compressor powered spray-gun, though some users apply the product with a brush or roller.

Fluid Film is a highly-rated brand, and their by-the-gallon Protectant and Lubricant is ideal for covering large areas quickly and easily. Owner reviews say that one gallon is roughly sufficient to thickly coat the underside of a large pickup. The product also lubricates hinges, chains and cables, and contains no solvents, so it won’t damage paint or rubber parts.

Electronic rust protection works on the principle of conducting an electrical current through the vehicle’s metal body to interrupt the rust formation process at the molecular level. Though the technology has been widely used in marine and underground tank applications for years, its effectiveness has been widely-debated in the automotive world for some time. Products like the Fin Corrosion Control module are discreet and easy to install quickly, but owner reviews of electronic rust protection products in general are mixed at best. (See notes from one of our experts below.)

Do your homework, first. If you decide to use a product like this one, simple ‘set it and forget it’ installation takes mere minutes.

Photo Credit: Sergey Vasilev 2701/Shutterstock

Rust forms when water molecules react with the iron found in the metal that makes up most of your vehicle’s body and structure. It’s created by a chemical reaction that literally transforms the ingredients involved, creating a new compound called an ‘oxide’, which weakens the metal and leaves an unsightly mess.

There’s no single, magic-bullet solution to prevent rust on a vehicle, and the best approach is typically multi-faceted. Spot treatment of rust-prone areas like door hinges, trunk latches, and sunroof openings may be combined with wider-coverage solutions for total protection. Some owners regularly treat the entire underside of their vehicle with a spray-on application designed to seal the vulnerable metal beneath the vehicle from moisture and salt, thereby preventing rust from forming. Keeping your vehicle clean, and removing any buildup of salt or sand possible is a good defense, too.

Further, note that surface rust typically forms rapidly when the paint is compromised with a deep chip or scratch. As such, timely and effective sealing of the vehicle’s painted surfaces, if damaged, goes a long way to keep rust from spreading.

Use extreme caution when considering an electronic rust module. These promise to stop rust from forming throughout your entire vehicle by conducting an electric current or ‘signal’ through its metal parts. Often, the module is powered by your vehicle battery and has several electrodes hooked up to conductive body parts. Though the science behind electronic rust protection is sound, it’s generally recognized as ineffective on a vehicle body.

“Electronic rust protection works, though it’s designed for applications like underground fuel tanks and large boats,” says Jeff Major, a collision repair technician. “Thing is, in those applications, the metal exterior surface is always wet or damp, allowing the signal to conduct powerfully and fully throughout the metal structure or body.”

Major works in Northern Ontario, where vehicles are exposed to large amounts of salt. When he repairs vehicles with body damage, he takes note of whether or not they have a rust module installed. Then, he inspects the body, beneath the body panels, for signs of rust.

Major’s hobby has led to an interesting observation. “I’ve yet to see a car with a rust module installed that isn’t rusting,” he says. “I was working on a new Corolla the other day that had a rust module installed at the dealership. This car hadn’t even seen its first oil change yet, and it had a rust module but was already showing some rust. In my opinion, these just don’t work as advertised. I haven’t been proven wrong, yet, and I wouldn’t waste my money on one.”

Avoid One Size Fits All: Though a general-use rust inhibitor is ideal for some applications, many users prefer to keep several specialized products in their garage, rather than a single formulation. This ensures you’ve always got access to the best possible product for the job at hand, without compromise.

Clean It First: Though the instructions in the rust inhibitor you’re using should be followed precisely, it’s typically a good idea to remove any dirt, debris, or loose existing rust from the area you want to protect before applying the product.

Choose the Right Product: Rust inhibitors are available in a multitude of general-use and application-specific formulations, each with a different purpose. Assess the rust area you want to address, and choose the right product for the job. If you’ll be applying the product on the exterior or underside of your vehicle, you’ll want to use a product designed not to wash away or drip. Thinner or more ‘runny’ rust inhibitors are generally best used for areas protected from exposure to the elements.

Preventative Maintenance: One of the best ways to keep your vehicle rust-free is to help stop rust from forming in the first place. Keeping your vehicle clean, regularly washing its undercarriage with fresh water in winter months, and preventing dirt, mud, leaves and debris from accumulating in or on its body are all great ways to discourage rust from forming. Treat paint chips and scratches on metal surfaces right away for even better results.

Read the Warnings: Don’t skip the warning label on the rust inhibitor you’re using. Some formulations can damage your vehicle’s paint, wiring insulation, rubber seals, and more. Not all rust inhibitors are compatible with all parts of your car or truck—so be sure to carefully read the warnings for best results.

Photo Credit: Cla 78/Shutterstock

If we were to compare rust to a disease, it will likely be cancer. It spreads rapidly if the conditions are right, if untreated it can destroy a body panel. And if you don’t get it repaired on time, it can even eat through the chassis rendering the car undrivable and sometimes outright dangerous. Many cars have been written off due to excessive rust. So if you notice your car is developing rust despite your best efforts, ensure you get it treated immediately. You can even treat rust at home but bear in mind you do need some automotive experience and know-how to treat the rust at home. So without further ado, here is how you can remove rust from your car at home.

Plastic Sheeting– To cover the vehicle and avoid damage to the area around the rust affected patch.

Painter’s tape– again as an added layer of protection for the unaffected areas.

Sandpaper– 180 or 320 grit to sand away the rust. You will need much more aggressive grit sandpaper in case the rust is deeper than the surface.

A grinder tool– again depends on the type and depth of rust

Wax and grease remover– To clean the affected area before you apply the primer or clear coat.

Body filler– to fill the areas that have been sanded away.

Paint matching the car color– for obvious reasons

Protective gear– Latex gloves, dust mask, and protective goggles to protect you from the fine dust and paint fumes.

Before we begin the procedure, there’s one thing you need to ascertain, the type of rust you are planning to treat. There are three types of rust that you will encounter, surface rust, scale rust and penetrating rust. Surface rust, as the name suggests is just on the surface of the metal. This is the initial stage where the rust has just begun to settle in and it is relatively easy to tackle if you treat it at this stage. You will rarely require a power tool to treat surface rust.

The second type of rust is called scale rust. This is when the rust has settled into the metal and has caused the metal to pit. You will need to be more aggressive in your approach to treat this type of rust and will require the grinder tool to get the rust out. You will need a lot more body filler as well.

The third type of rust is penetrating rust and as the name suggests, it is the type that causes holes in the metal. And there is no going back from this stage. If you have penetrating rust, that body panel will need replacement.

Photo Credit: Suza Zoom/Shutterstock

Note: You don’t need body filler for surface rust.

Photo Credit: Vector Lab 2D/Shutterstock

With scale rust, follow the surface rust steps till step 3 where you clean the surface with the wax and grease remover. For the next step you will need the grinder tool