Most vehicles built in the 1990s and older featured a number of different drive belts to transfer mechanical power from the engine’s crankshaft to other components such as the alternator, water pump, power steering, and air conditioning compressor. In older vehicles, these systems used a number of belts in various sizes and designs, but eventually, newer vehicles switched to a single serpentine belt. This type of drive belt is a flat, rubber belt that is ribbed on one side and smooth on the other. It snakes through all of the various pulleys on an engine. Depending on the specific vehicle, tension is applied to the serpentine belt either through a tensioner that is either manually adjustable or spring loaded. Both types of tensioners ensure that the belt is always tight.

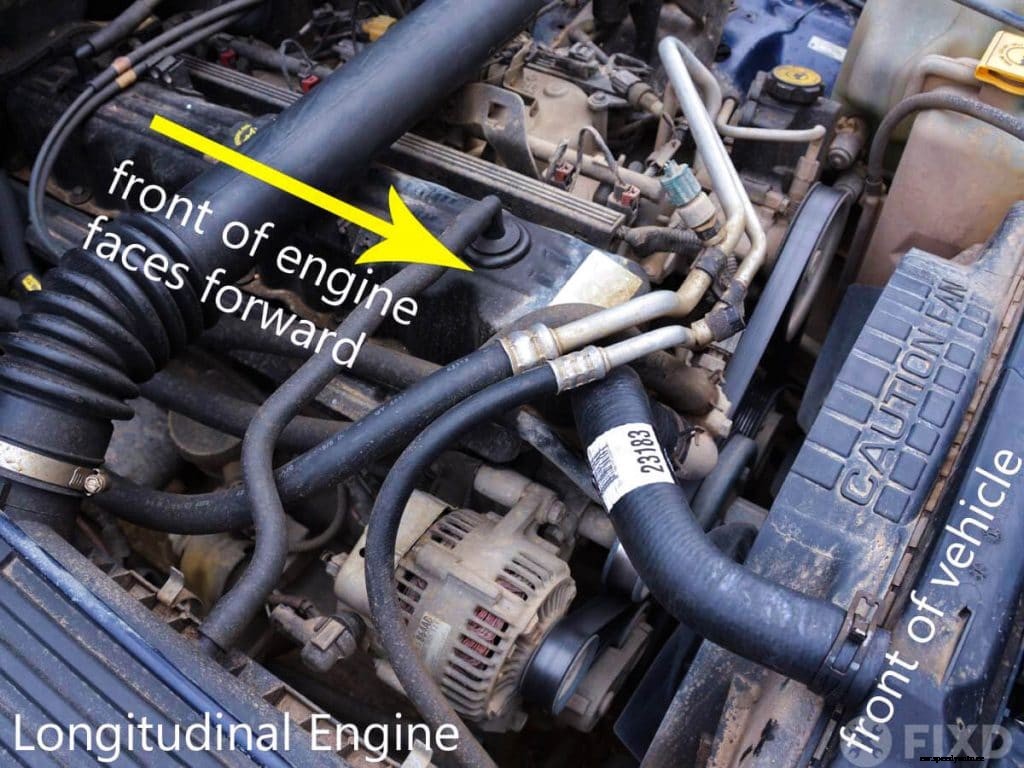

There are two types of engine layouts that will determine where your serpentine belt is and how hard it will be to replace. With a few exceptions, the majority of trucks, SUVs, and rear-wheel-drive cars have what is called a longitudinal engine layout (pictured above) where the engine’s crankshaft is facing forward and the transmission is mounted behind the engine. Most vehicles today are front-wheel-drive (or FWD-based vehicles that are all-wheel drive). These cars will usually have a transverse engine (pictured below) where the engine’s crankshaft is perpendicular to the direction of travel and the engine and transmission sit side-by-side in the engine compartment. Replacing the serpentine belt on a longitudinal engine tends to be far easier than on a transverse engine.

Performing regular preventive maintenance such as replacing the serpentine belt will help keep your car running and on the road… even for a million miles! And if you’re buying a used car, checking the condition of the serpentine belt is just one way to gauge how well the vehicle was maintained.

If you get to the recommended mileage and the serpentine belt doesn’t look damaged or worn, it normally doesn’t hurt to put a few more miles on it. You’ll just want to keep a closer eye on things. If you do notice cracks in the rubber or a glazed appearance to the belt itself, then it could become unsafe to keep driving with that belt.

At the very least, a worn-out serpentine belt could cause a loud squealing noise when the belt gets wet. If the belt breaks, it could result in the vehicle losing power steering, air conditioning, alternator, and even the water pump. A non-functional water pump will lead to overheating and potential engine damage.

Based on the average cost to replace a serpentine belt and a beginner-to-intermediate difficulty level (depending on how easy/hard accessing the serpentine belt is), this job is definitely worth tackling at home. It might take an hour or two to complete, but you will save money by doing the work yourself and getting the new serpentine belt from your local auto parts store.

The service schedule for serpentine belt replacement varies widely by different automakers as well as specific makes and models, but generally speaking, you’ll probably need to replace the belts every three or four years. If you want to keep track of important maintenance like replacing the serpentine belt on autopilot, be sure to check out FIXD.

Replacing the serpentine belt on a longitudinal engine is usually pretty straightforward since there tends to be more room to access the belt, but transverse-mounted engines are a little more difficult to work on.

To determine whether or not this is a job you’re willing to take on, open the hood and look at the engine compartment. If there is easy access to the belt, then it should be an easy job. If your engine is transverse mounted and it’s hard to access the belt, then you might want to consider letting a professional do the work.

The serpentine belt is a wear item, so you’ll want to replace it as a part of the manufacturer’s recommended maintenance schedule. You can find the specifics for this in your owner’s manual or in the FIXD app, but usually manufacturers recommend replacing the belt between 50,000 and 100,000 miles.

Since the serpentine belt is routed around various pulleys (like the idler pulley and tensioner pulley) and components (air conditioner compressor, power steering, etc), this would also be a great time to check the condition of these parts. While it’s not necessary, having the replacing parts such as the idler pulley, tensioner pulley, and water pump at the same time as the serpentine belt will end up saving you money in the long run, because removal of the belt is required to replace these components.

With the engine cold, open the hood and locate the serpentine belt routing diagram, which is usually found on a sticker under the hood near the front of the engine compartment. If there is no sticker, check the owner’s manual or take a detailed picture (or make a hand-drawn diagram) of how the belt is installed before you remove it. You will definitely want to have some sort of reference for how the belt is routed for when it comes time to put the belt back on.

Most serpentine belt systems use an automatic spring tensioner, while others use a manual adjusting tensioner. A spring tensioner just needs to have pressure applied to it to relieve tension from the belt allowing the belt to come off easy. Once the belt is off, you should check (visually and physically) the condition of the various engine pulleys. If one of them looks damaged or feels loose, this is the best time to address any potential issues.

Following the routing diagram, snake the serpentine belt around all of the pulleys. The smooth side of the belt goes on smooth pulleys (as shown on the idler pulley pictured above), while the ribbed side wraps around the grooved pulleys. Each car is different in terms of the easiest way to route the belt, so sometimes it helps to start from the bottom while other times it actually works better ending at the lowest point, the crankshaft.

Once the belt is loosely fitted on all of the pulleys, release tension from the belt tensioner and then slide the serpentine belt onto the tensioner. Once you reapply tension to the serpentine belt, double check that the belt is properly routed on each pulley before starting the engine.

Get the FIXD Sensor and free app today for a custom maintenance schedule based on your make, model, and mileage. Never miss important maintenance again with automated maintenance alerts! Learn more at fixd.com.