It wasn’t that long ago that turbochargers were only used in big trucks and race cars. Since then, turbochargers have become a practical solution to the ever changing engineering demands that are challenging modern auto manufacturers.

Today’s consumer demands fuel economy without sacrificing power, and the EPA continues to set emission standards that keep getting lower every year. Enter the turbocharger.

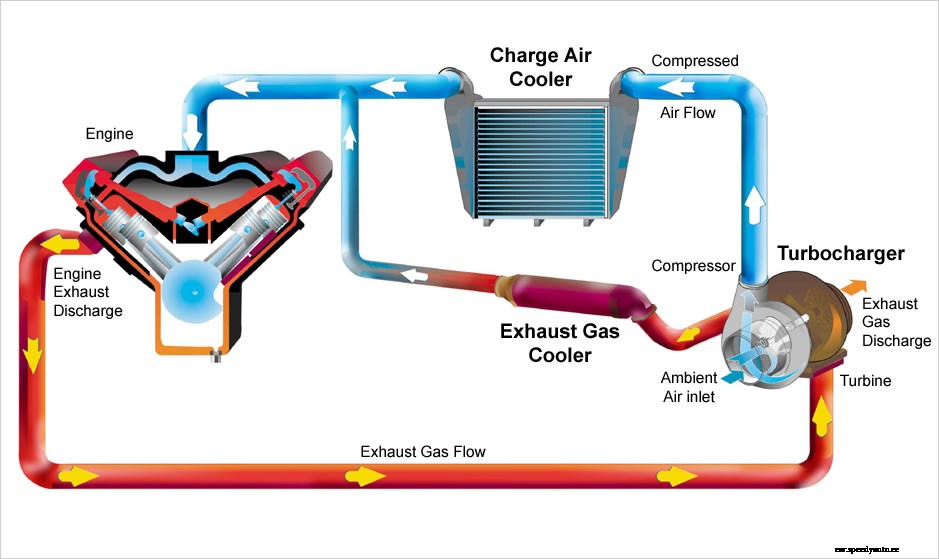

A turbocharger uses free energy created by exhaust pressure, to drive a compressor that pushes air into the engine for the purpose of creating horsepower.

Car engines burn an air/fuel mixture that is ideal at 14.7 parts air to 1 part fuel. Most car engines are naturally aspirated, this means that all the air that enters the engine is sucked in by the natural vacuum that is created by an internal combustion engine. The air and fuel enter the combustion chamber where it is burned to run the engine.

The thing is, that the more air/fuel mixture you can stuff into the combustion chamber, the more power it produces. That’s where forced induction comes in, and that’s what a turbocharger does.

A turbocharger consists of two halves. One half is an air compressor that compresses air and forces it into the engine. The other half is a turbine. The turbine is attached to the compressor and is spun by exhaust pressure. So on its way out of the tailpipe, the exhaust takes a detour through the turbocharger and spins the turbine. The turbine spins the compressor, which forces air into the intake manifold, through the intake valves, and into the combustion chamber.

The beauty of the turbocharger is that it uses free power. The air compressor would be using up engine power if it was driven by the engine via a belt or a chain. So the horsepower it consumes would have to be subtracted from the horsepower it produces. Exhaust pressure is wasted power that is being put to task.

Since cold air is denser than hot air, the internal combustion engine runs more efficiently on cooler air. This creates an issue because the compressed air that exits the turbocharger is hot. Very hot. Sending this hot air through the intake manifold and into the combustion chamber almost defeats the purpose of forced induction. An air/fuel mixture that is too hot hinders combustion, which in turn hinders horsepower.

To solve this problem turbocharged engines are equipped with a charge air cooler. The cooler is located in front of the radiator. Compressed air from the turbocharger is pushed through the charge air cooler before it enters the intake manifold. This cools the air down for more efficient combustion.

The amount of air that a turbocharger pushes is called boost. Turbochargers are capable of producing enough boost to cause some serious engine damage, this is referred to as over boost. So the amount of boost needs to be governed. This is done with the help of a waste gate. When boost pressure exceeds a predetermined limit, the waste gate opens diverting exhaust pressure away from the turbocharger, limiting boost.

Today’s turbochargers are mostly controlled by electronics. Electronic modules receive data from numerous sensors. The modules use this information to control the waste gate, bypass valves, and numerous components.

So the job of a turbocharger, as stated earlier, is to use free energy created by exhaust pressure to drive a compressor that pushes air into the engine for the purpose of creating horsepower. This allows manufacturers to use smaller engines without compromising performance. Smaller engines use less fuel, and nothing sells a car, like lots of miles per gallon.