When LG Chem first announced the construction of a battery plant in Poland, the company made it clear that it would be its most important factory.

In October last year, at the groundbreaking ceremony, Lee Ung-beom, LG Chem’s energy solution chief said the following:

“We will turn the Poland EV battery plant into a mecca of battery production for electric vehicles around the world”.

Then he added:

“As LG Chem’s Poland EV battery plant is the first large-scale automotive lithium battery production plant in Europe, it will play the role of vitalizing the electric vehicle industry across the whole Europe”.

Nevertheless, the initial planned annual output capacity was “only” of 100.000 EV battery packs, clearly not enough in the long run. For this reason, LG Chem reconsidered the total investment it will make to expand the battery production capacity.

By June 2020, LG Chem will invest around 327 million euros in its battery cell plant in Poland, 27 million euros more than what was initially planned. Furthermore, according to the Polish daily newspaper Puls Biznesu, the next step is to invest even more, at least 800 million euros.

A company like LG Chem doesn’t announce this kind of investments without profitable supply contracts already signed. Again, according to Puls Biznesu, the numbers are impressive:

“LG Chem has revealed it has orders for 36 trillion won of batteries for 82 projects made by 28 global automakers.”

Those contracts that worth 27.000 million euros represent a lot of battery cells to be supplied by four LG Chem plants. If we consider 120 € per kWh, that amount is enough to buy 192,86 GWh of battery cells. Anyways, most of these orders should be only for electric cars to be made between 2020 and 2030 – that will get big battery capacity packs, the Jaguar i-Pace for example will have 90 kWh.

Now let’s go back to the Polish battery cell plant…

Without a doubt, currently, LG Chem’s most valuable customer is Renault, which builds its electric cars in Europe.

Let’s see some reasons why LG Chem considers its European plant the most important.

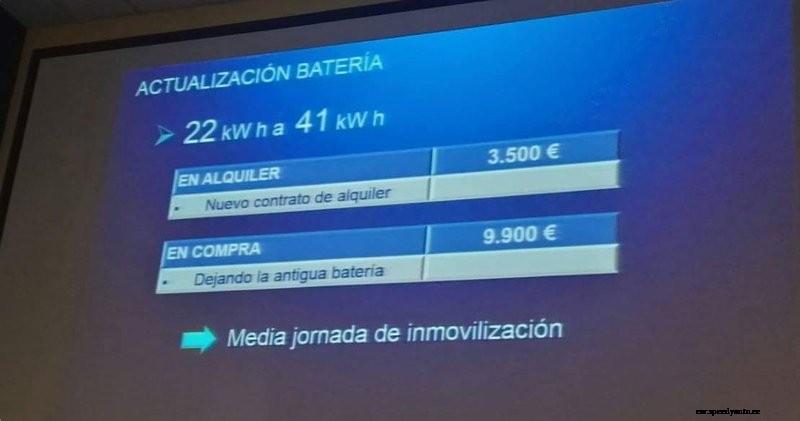

Right now, LG Chem not only needs to supply the ZE 33 battery for the Renault electric ZE vans (Kangoo and Master), but also the ZE 40 battery for Europe’s best selling electric car, the Zoe. Furthermore, Renault needs more ZE 40 batteries to allow the battery upgrade for old Zoes, which is already happening but at a very slow pace.

Renault battery upgrade prices

Then we have the Nissan Leaf, which is very popular in Europe and sooner or later will have LG Chem batteries.

By 2019, we’ll also have PSA selling electric cars powered by LG Chem battery cells.

At a smaller scale we can add Smart to the list, since it’s already selling their electric cars with tiny 17,6 kWh LG Chem batteries…

Anyways, the imminent introduction of the much improved 2018 Nissan Leaf at around 30.000 €, will definitely pressure Renault to adjust the Zoe’s price to at least 25.000 € with battery included. With a smaller price tag the Zoe’s demand and consequent production will definitely increase. Furthermore, the probable introduction of the Renault Twingo ZE will further increase the need for LG Chem batteries.

LG Chem expects its battery cell plant in Poland to start production in December this year, we’re just 3 months away.