The imminent arrival of NCM 811 battery cells for EVs, which combine high energy density with low cost, finally convinced Chinese companies that the technology is ready for mass production.

EV batteries are about to experience the same revolution that solar panels had when Chinese companies started mass production and costs rapidly declined. You may not remember the old days when solar panels were really expensive. However, it was only when the Chinese Government decided it was time to make solar panels mainstream, that Chinese companies started mass production and prices dropped very fast. Now something unimaginable years ago is a reality, the cheapest electricity in the world is Mexican solar power at 0,015 euros per kWh.

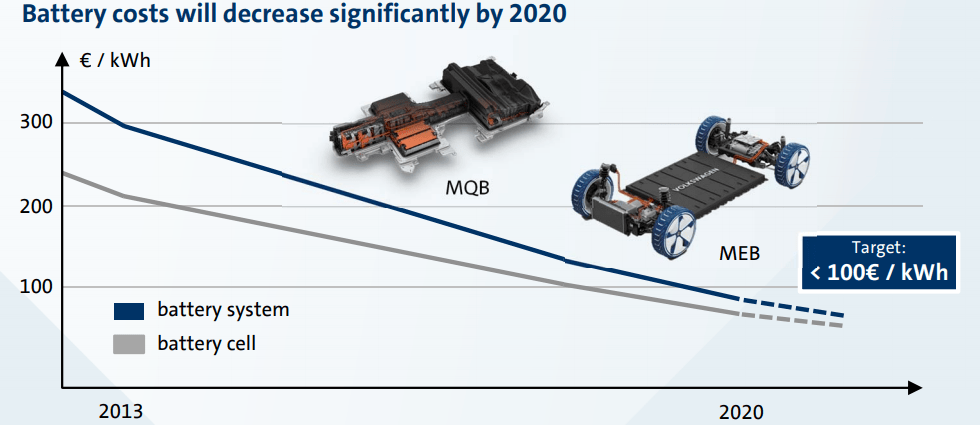

With NCM 811 battery cells the kWh cost will drop to below 100 euros already next year. Volkswagen will be able to achieve 100 euros per kWh at the pack level by 2019 with the introduction of a dedicated platform for EVs (MEB). A simplified platform like MEB can improve heat dissipation and reduce the use of cables, making battery packs easier, faster and cheaper to assemble.

Battery costs roadmap by Volkswagen

When the Chinese companies start mass producing NCM 811 battery cells they’ll have the advantage of easier access to raw materials and I expect the kWh cost drop to 80 euros initially and coming close to 60 euros when the second generation (solid-state) arrives in 2020.

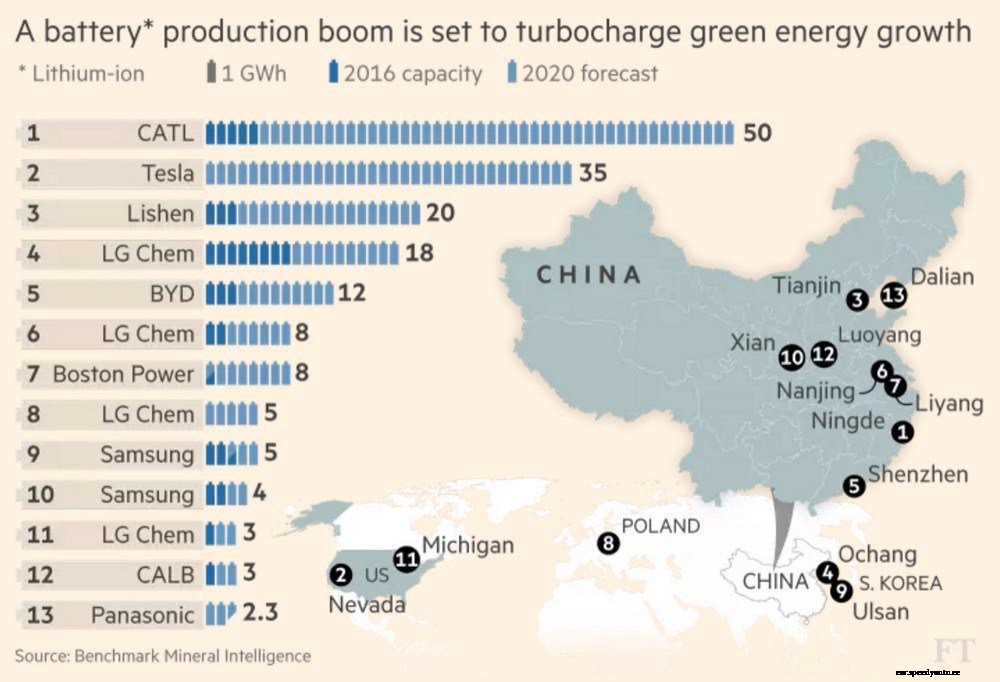

Right now CATL is actively trying to secure some battery supply deals with European automakers and is seen as a big threat by South Korean battery cell makers. Volkswagen and Renault are by far the main targets of CATL’s efforts, that’s why the company has offices in Germany and France.

Anyway, while I think that CATL will thrive in China, to get the European automakers it’ll have to produce the battery cells locally. Decentralization is the key strategy to succeed in a booming market and LG Chem was smart enough to localize production in four different countries (South Korea, China, USA and Poland).

Battery cell production targets by manufacturer

To sum up, the South Korean battery cell makers will make possible to build electric cars price-competitive with ICE (Internal Combustion Engine) cars very soon, but the Chinese are the ones that will achieve a much more impressive feat, make electric cars not only better overall, but also cheaper than their ICE counterparts.

What do you think? Will the South Korean battery cells makers survive the imminent arrival of the Chinese and their lower prices?