So, it never fails! Just when you think you have got the whole job taken apart and everything is under control. You either twist off a nut, break or round off a screw, or strip out the threads entirely.

Broken bolt and stud removing, can often be a frustrating time-waster with no quick fix available.

More often than not, removing the broken piece and/or repairing the broken threads; can take longer than all the whole job itself. There are however, a few tips, tricks and tools, that might make the job easier. So, the job can’t proceed until the fastener is removed. And, of course, you didn’t allow for all that extra time, did you? What to do now? What alternatives are there to get the bolt out? Probably the best piece of advice is, not to panic.

There are, in fact, many different ways to get broken bolts and screws out. Which method you use, will depend upon the circumstances and also your available tools.

On top of this, they should also know about the different parts of a drill; as well as how to a drill correctly.

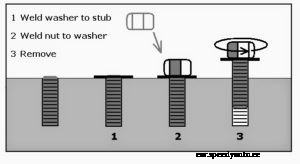

So, If there is a stub sticking out, an effort must be made, to grab it with Vise-Grip locking pliers.

If it can’t be gripped, try to carefully turn it out of the hole, with a hammer and chisel. A bolt remnant that has broken off flush or below the surface of the work piece; will usually be loose in the threads. In such a case, it often works to carefully use a punch or chisel; and drive on the outer perimeter of the bolt to turn it counterclockwise.

If the above efforts fail, then you will need to:

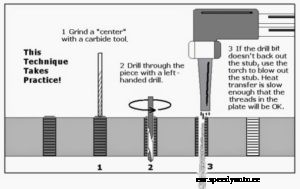

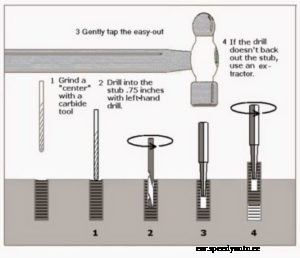

One often overlooked method of removing broken screws and bolts; and perhaps the best first choice, is the left hand twist drill bit. These are the same as regular high speed drill bits; except the cutting action is in a counterclockwise direction. As a result, it might just unscrew.

Since you will likely have to drill a pilot hole at this point anyway; if you use a left hand drill bit; in many cases the drilling process results in removal. Because, you are turning and biting into the stuck fastener in the same direction as removal; while applying downward pressure. For this reason, you should be looking at some of the better quality drill bits; as to not damage any component that you’re working with. So, perhaps go to your local store or look around online; to view the top drill bits available to you.

Often a last resort, the application of heat to a stubborn, immovable fastener, can be the catalyst for success. So, why apply heat? Because, it excites the molecules in the metals causing expansion. This expansion can take place at different temperatures and rates for different metals.

One of the most common examples is the heating of cast iron manifolds to remove stubborn steel studs.

Being dissimilar in structure, the cast iron heats and expands at a rate, greater than the steel fastener. As a result, allowing a space to form, between the two and facilitates easier removal. The added use of penetrating fluids that can withstand high temperatures, enhance the chances for success.

If all these methods fail to remove the broken bolt; then the only choice is to drill it out completely. The one downside is, this means drilling away the mating threads. In this case you will have to tap new; larger threads into the hole and find a larger bolt.

If you can not use a larger bolt, because of specific fit or appearance reasons? Well, in such cases you can obtain a Heli-coil kit or use the Time Cert Method. This will allow you to machine the hole back to the same size hole.

Good Luck Patience Is everything !!

Finally, don’t make the job worse, by turning it the wrong way.

The easiest way to remember which direction tightens and which one loosens is the old axiom.

“righty-tighty and lefty-loosey.”