Above all, To maximize performance and longevity there is a proper gasket to use on the GM 6.6L Duramax Diesel. But, only after you have confirmed the piston protrusion. Because, Using the wrong head gasket on this engine could cause engine damage.

Important Note:

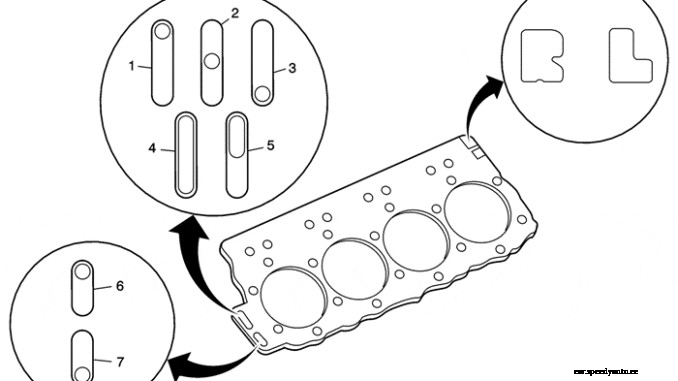

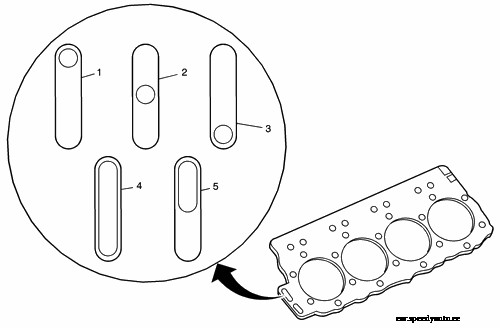

The left and right cylinder head gaskets are not interchangeable. As a result, Improper placement of the cylinder head gasket will block coolant and oil passages. Hence, Blocked coolant and oil passages will cause severe engine damage. But, It is physically possible to install the head gasket “flipped” end-to-end. The gasket markings should be up when correctly installed.

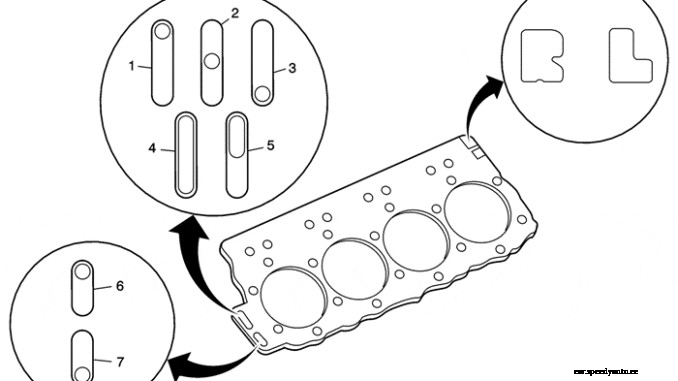

Consequently, GM offers three different thickness head gaskets depending on the amount of piston protrusion the engine has.

There are also different head gaskets for the left and right bank of the engine. So, Measure piston protrusion to confirm you are picking the correct gasket. Also, Always check both sides as they are not always the same.

Use a dial indicator on the deck surface and check the piston, in two different locations on each bank.

Finally, Place the pointer right above the piston pin centerline to prevent inaccurate readings. As a result, Of the piston rocking in the cylinder bore. Rotate the engine through (TDC) while noting the maximum reading on the dial indicator.

Obtain the maximum value of protrusion for each bank of cylinders. Determine your gasket options using the information below.

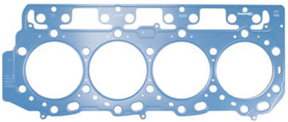

Well , Felpro has solved that problem for you. It is your choice but this is what most people are using.

So, The GM Duramax 6.6 diesel is a great engine. But, If you keep it long enough, you will probably be replacing the head gaskets at some point. So, If you are using aluminum heads, with a iron block, sooner or later you will have head gaskets issues.