Learning about the differences between the serpentine and timing belt is important if you’d like to gain a greater understanding of how the internal-combustion engine works. The two belts serve entirely different purposes, but they’re both instrumental in keeping the engine running.

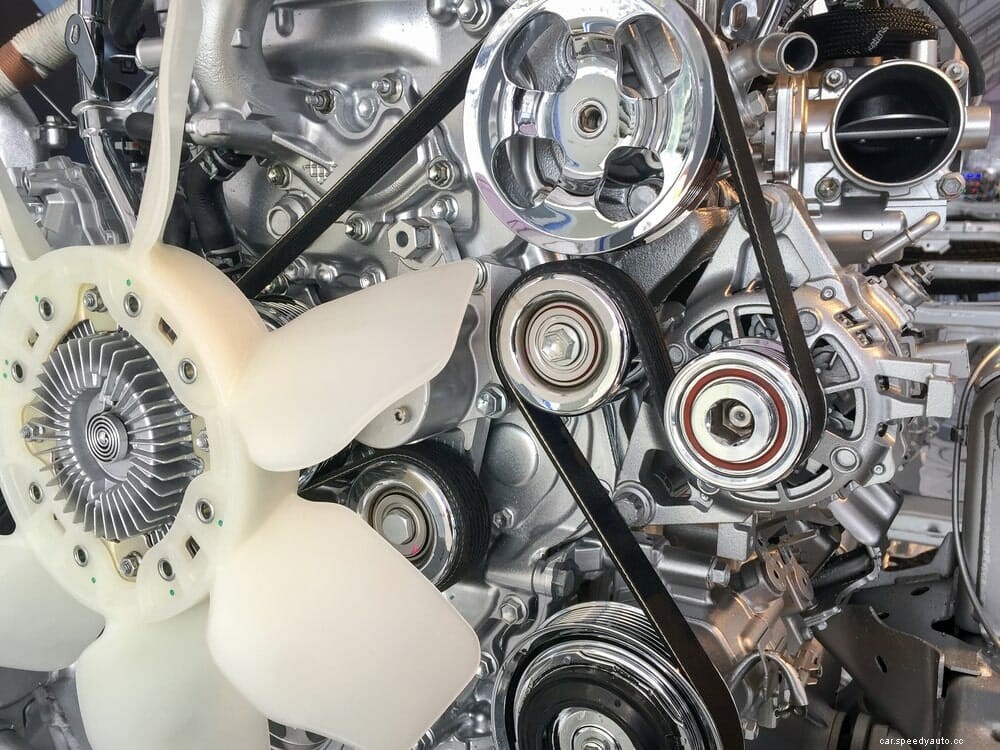

The serpentine belt has been named after numerous bends in its path, and it’s also known as the drive belt. It powers the auxiliary systems and is visible at the front of the engine.

The timing belt synchronizes the crankshaft with the camshaft. It can be found at the front or back of the engine, and it’s hidden behind a cover.

| Timing Belt | Timing Chain | Serpentine Belt | |

| Purpose | Synchronizes engine operation | Synchronizes engine operation | Power auxiliary systems |

| Location | Front or back of the engine, covered | Front or back of the engine, covered | Front of the engine, exposed |

| Replacement Interval | 40,000 – 60,000 miles | 80,000 – 120,000 miles | 30,000 – 60,000 miles |

| Parts Cost | $100 – $200 | $200 – $400 | $100 |

| Labor Cost | $400 – $1,000 | $400 – $1,000 | $100 – $200 |

The serpentine belt is used to power the alternator, air conditioning, the power steering pump, supercharge, and sometimes the water pump.

Originally, serpentine belts were called drive belts and had a much simpler design, as they only needed to transfer the power from the crankshaft to the water pump, alternator, and radiator fan. Depending on the design, cars could have one or two drive belts.

The modern serpentine belt is designed in such a way to maximize coverage while the footprint of the engine.

A single belt requires only one crankshaft pulley and reduces the overall length of the engine. The radiator fan can be powered by the belt, but the advancements in technology allow for the use of electric motors instead, thus separating the engine from the radiator.

The crankshaft pulley provides the power for the serpentine belt to transfer. It is always located at the bottom of the engine, where the oil sump is. The auxiliary systems are placed where they take up the least room, and the serpentine belt has to accommodate them.

This is done through the use of idle pulleys that change the angles of approach to provide more contact between the belt and the auxiliary system.

There is a difference between the two sides of the serpentine belt. The interior side features grooves that go along the length of the belt and provide better traction when it comes in contact with grooved pulleys of auxiliary systems, like the AC, alternator, and power steering.

On some vehicles, the water pump is powered by the smooth side of the belt, as are some of the idle pulleys.

The belt doesn’t have directional grooves, but matching the belt side and pulleys is very important for its functionality. The belt should be under constant tension, but over time the rubber will stretch. That’s where the belt tensioner comes in, a spring-loaded pulley that automatically tightens the belt when necessary.

The timing belt has a singular purpose – to synchronize (time) the rotation of the crankshaft with the camshaft. The system consists of the timing belt, camshaft pulley, crankshaft pulley, and belt tensioners. In some configurations, it also drives the water pump.

The timing chain is an alternative to the timing belt but serves the exact same function. We’ll cover the differences between the two in another section. To really understand what’s going on we have to talk about some of the basics of internal-combustion engine operation.

The crankshaft is positioned at the bottom of the engine and is connected to the piston via the connecting rod. The cranking mechanism converts the linear force of the piston into a rotational force. The rotational power is transferred to the serpentine belt, timing belt, and transmission to power the vehicle.

Pistons compress the air-fuel mixture and detonate it either through pure compression (diesel) or with the help of a spark plug (petrol). To ensure this happens, the intake and exhaust valves have to open at the right moment.

This is where the timing belt comes into play. Located on the front or backside of the engine block, the timing belt connects the crankshaft to the camshaft and synchronizes their movement. The camshaft looks like a rod with a series of egg-shaped cams on it.

Each of the cams gradually opens and closes one valve. Engines can have one or two camshafts, commonly referred to as OHC – overhead camshaft and DOHC – dual overhead camshaft.

You might be realizing why we say “crank the engine”. In the early automotive days, a starting handle would have to be inserted from the front and crank the engine to get it running.

With the invention of starters, electrical current is used instead to automate the process, but the concept remains the same. The first cycle of the crankshaft and therefore pistons and camshaft has to be done manually until the detonations generate enough force for the pistons to take over.

The reason why some people are confused about the differences between the serpentine and timing belt, or even think they’re the same thing is due to the maintenance cycle.

The interval for changing the serpentine belt and timing belt is usually the same. I was taught that the belts should be changed every 35,000 to 50,000 miles, but modern belts can last up to 100,000, so it’s best to check the manufacturer’s recommended maintenance schedule.

The water pump is usually changed as well because it has a similar lifespan and it saves a lot of money on labor costs should it be changed independently. While we’re talking about costs, I should state the general cost of replacing the belts.

Serpentine belts cost between $15 and $70 but it’s a good practice to change the idle pulleys and the belt tensioner at the same time – they cost around $25 each. You can also find a complete kit for less than $100.

The cost of labor ranges between $70 and $150, bringing the total to $200, but this job can also be done at home with some skill and the right tools.

The timing belt isn’t very expensive – between $50 and $100. The problem is the labor cost, as replacing the timing belt requires you to open up the engine.

It’s usually accompanied by an oil and filter change and other maintenance can be grouped in to reduce the overall cost. The labor will set you back $500 – $1,000 depending on how the engine is positioned and whether the belt is facing the back of the engine.

Even though we’re talking about belts, the timing chain is a widespread alternative to the timing belt and has to be mentioned. The difference between the belt and the chain is in the material – the chain is made out of metal and lasts longer.

An old rule of thumb says that the timing chain lasts twice as long as the timing belt. This is not entirely true, especially now that timing belts can also run for 100,000 miles, but the chain is still the more durable option.

The timing chain kit costs between $200 and $400, which is more expensive than the timing belt, but the cost of labor is the same, $400 to $1000, depending on the location.

If the chain is located at the back, as was infamously done on early 2000s BMWs, the entire engine needs to be pulled out to gain access.

Before we get into the symptoms, I want to emphasize one thing. If you start noticing symptoms of timing belt wear, you should act immediately and get it replaced.

Timing belts are changed in set intervals regardless of condition to make sure it doesn’t break, as the snapping of the timing belt can cause catastrophic engine damage, or at the very least bend the valves.

These are the common symptoms of timing a failing timing belt:

You may hear a rolling noise coming from the engine, and if you can identify that it’s not coming from the serpentine belt, then it’s likely caused by a timing belt problem. The computer may report a crankshaft/camshaft error, and you could experience rough starts and misfires as the belt slips.

My advice would be not to rely on these symptoms as the early warning signs of timing belt failure because it often comes without any warning. Maintenance book and schedule are the only certain ways of staying ahead of serious engine problems.

A few years back, I had a VW Passat that had approached its timing belt change but ran perfectly otherwise. Instead of changing the belt, I decided to sell the car with a notice that the belt had to be replaced.

The new owner didn’t take my advice, and less than 6 months later the timing belt snapped. Luckily, the engine survived without any damage, but that was a one-in-a-million occurrence.

The serpentine belt offers some advantages over the timing belt in terms of maintenance. It’s easy to inspect and it will show symptoms of wear to prompt you to replace it. The cost of a new belt and labor is $250 at most, which is not a lot considering its importance.

These are the common symptoms of a failing serpentine belt:

Because it’s responsible for powering the auxiliary systems, when the serpentine belt goes bad you’ll experience a number of problems. The slipping of the belt will affect how some of the parts work, so you might experience occasional loss of power steering or lack of AC as the roller slips in contact with the belt.

The squealing noise is not always a cause for concern, as it means the belt has compressed in cold, but if the noise persists the belt should be replaced. The same applies if you hear rolling noise or if the belt feels loose as a result of a failed tensioner.

When one of the components fails, you should replace the entire set.

The check engine light will warn you where the problem is coming from. Alternator rellies on the serpentine belt for power and without a constant charge it’s possible for the battery to deplete. The most serious problem is the water pump, as insufficient coolant pressure could cause the engine to overheat.

There’s nothing we can do about the timing belt as it requires skills far above a DIY mechanic, but replacing the serpentine belt is a different story. The process of getting the belt off is simple, but the main issue is going to be accessing it. If the engine bay of your vehicle is too cramped, it might be better to leave the job for a professional and save yourself a day’s worth of hassle.

| Image | Title | Price | Buy |

|---|---|---|---|

| Gates 90K-38274 Complete Serpentine Belt Drive Component Kit | Buy Now | |

| DEWALT Mechanics Tools Kit and Socket Set, 142-Piece, 1/4 & 3/8" Drive, MM/SAE (DWMT73802) | Buy Now | |

| Powerbuilt Alltrade 648629 Kit 52 Serpentine Belt Tool Set | Buy Now |

To pick the right serpentine belt kit, you need to know the make, model, model year, engine displacement, and power. Alternatively, you could search for the right part by using the VIN number. A regular socket set is enough to get the job done, but you could also use a specialized serpentine belt toolkit that makes the job a little easier.

Technically yes, because the serpentine belt is a type of drive belt, and almost all vehicles use it. However, old vehicles did not have serpentine-shaped belts and instead used simple 2 or 3-point drive belts.

They are not, and you’re probably thinking of the drive belt that serves the same function as the timing chain but is made out of different materials.

There are pros and cons to both systems. A timing belt is cheaper and should cost less to replace, but it has a set maintenance interval so you might go through multiple belts if you keep your car for a long time.

On the other hand, the timing chain is more expensive, but it lasts 50% – 100% longer than the timing belt. Some drivers don’t change the chain at all, which isn’t recommended, but sometimes it makes more sense from a financial standpoint.

Timing gears are the longest out of all synchronizing systems, but they’re noisy and require a lot of lubrication to run properly. Almost all modern vehicles use either a timing chain or a timing belt.

As the belt synchronizes and powers the camshaft through the crankshaft, when the belt snaps, the camshaft will stop in place while the crankshaft and pistons continue to move. The valves stuck open will be struck by pistons, which will bend or break them.

The belt alone can be replaced in just 30 minutes, but if you add the belt tensioner and the idler pulley, the job will take one hour at most. Most of the work revolves around gaining access to the belt, rather than working on it, as swapping the belt takes just 5-10 minutes.

It’s a common practice with BMW, Mercedes, Cadillac, and a few other manufacturers to use timing chains instead of timing belts. If you’re not sure if a car has a timing belt or a chain, a quick google search will give you the answer, but if you’re already on location and looking at the used car, check the service book.

Vehicles that have a serpentine belt don’t need an alternator belt because the design of the serpentine belt covers the alternator pulley. The term alternator belt is used for older vehicles that had dedicated drive belts, so you might have heard of an alternator belt, A/C belt, and fan belt used to describe them.

When the belt breaks, there’s a small chance that it coils around one of the pulleys still in motion and damages the component, but again, this is not likely. The moment the belt breaks, you’ll lose power steering as there’s nothing driving the pump.

The A/C won’t work, and the dashboard will light up with all the warning lights. The battery won’t receive a charge as the alternator isn’t spinning, but most importantly, the water pump will stop circulating coolant through the system, which can quickly lead to overheating.

Should your serpentine belt break, stop your car immediately and see whether you can do an on-site repair. If nothing is broken, the only tool you need is a ratchet to release the tension on the belt tensioner and a new belt.

The noise coming from the serpentine belt is an indicator that it needs to be replaced. The noise can be caused by the failure of the belt tensioner, worn-out pulley, or cracks in the belt itself. Lubricating the belt will make the noise go away temporarily, but it won’t solve the underlying issue.

No, it’s simply not reasonable to expect a rubber belt to last through all that mileage and season changes through the years. The maximum service life of a serpentine belt is one-third of that number, and even then you might experience belt slipping, irregular behavior of the auxiliary systems, and belt noise.

The only things you need to start the car are the battery, starter, fuel, and the engine, so the serpentine belt isn’t necessary. However, at the very least you need the belt to power the water pump and cool the engine, as well as to run the alternator and recharge the battery.

If you need to start the engine without the serpentine belt, only do so when you’re making repairs and checking how the engine runs.

The drive belts (serpentine belts) are engine-specific, so they’re far from universal. The length width and bends in the belt’s path are carefully designed, so you cannot use a random belt for your vehicle.

The serpentine belt is responsible for the squealing noise that can be a common occurrence on less-than-new belts during cold weather. A couple of seconds of squealing noise isn’t a cause for concern, but if it’s persistent, you might need to change your belt and check the pulleys.

Replacing, or even checking the condition of the timing belt is a task for a professional mechanic. The general idea is to inspect the condition of the grooves and sprockets to see whether there are any signs of wear and tear.

The differences between the timing belt and the serpentine belt are significant enough for you to remember. The replacement intervals are similar so you can swap them at the same time, but you should always stick with the interval for the timing belt, while the serpentine belt can be changed as needed.

VehicleFreak is a website dedicated to sharing useful tips, DIY guides, and reviews, so if you’re interested in learning more about cars, trucks and SUVs, take a look at our article list and see if anything catches your eye!