The cooling system is the unsung hero of the internal combustion car engine. It quietly keeps your engine at operating temperature, preventing overheating, and all the while supplying toasty cozy heat to the passenger compartment. The only time we notice the cooling system is when it fails, and that can quite often be catastrophic.

The temperature inside the combustion chamber of a car engine, (the area where the fuel burns) can easily reach as high as 1600 deg. F. Operating temperature of the engine should be in the low 200 degree range. That’s a lot of heat that has to be removed. Engine operating temperature depends on the temperature of the coolant. Engine damage can happen fairly quickly when coolant temperatures start to rise near 300 degrees.

An engine cooling system works on the principal of heat transfer. Heat transfer is the movement of heat energy from one place to another. Heat energy will always seek out something cooler. A good example of this is putting a warm can of soda (beer) into a cooler of ice. Since heat energy will always move to something cooler, the heat energy in the can transfers to the ice, making the can cold. Cold, by definition, is the absence of heat energy.

Here’s how an automotive cooling system uses the mechanism of heat transfer to keep your engine cool and your tootsies warm:

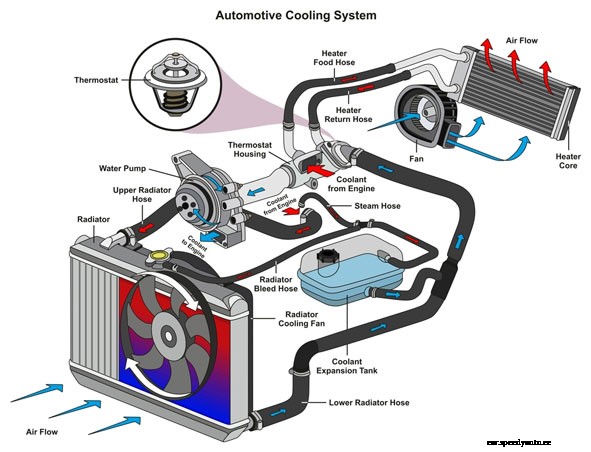

The water pump circulates coolant through the cooling system. The water pump is driven by the same accessory drive belts that operate the alternator, power steering pump, and the air conditioner compressor. These belts are driven by a pulley on the front of the crankshaft. The water pump uses spinning impellers to push coolant through the engine, radiator, and heater core.

Coolant flows through the engine via water jackets. Water jackets are throughout the entire engine, but are concentrated mostly around the combustion chambers, as this is where the heat is generated, and where the temperature is the highest.

The thermostat controls the flow of the coolant. The thermostat is the gatekeeper of the cooling system. It uses a spring operated poppet valve that is closed when the engine is cold, blocking coolant flow, and usually opens at a coolant temperature of 185 – 195 degrees, depending on the rating of the thermostat.

When the thermostat is closed, it inhibits coolant flow through the radiator. Coolant is directed through the engine by way of a bypass hose. This allows the coolant to heat up without the cooling effects of the radiator trying to cool it down. This way the engine and the coolant are able to reach operating temperature.

When it achieves the operating temperature, the thermostat opens, allowing coolant to flow through the radiator. The thermostat uses a bimetal spring. This means that the spring consists of two separate metals that contract and expand differently when exposed to changes in temperature. As the hot coolant heats the spring, both metals pull against each other, causing the spring to contract, which opens the poppet valve, allowing the coolant to flow.

Once coolant is flowing through the radiator, it continues on a cycle of heating up and cooling down. As the coolant passes through the engine, heat goes from the hot engine to the coolant. This extremely hot coolant is then pumped through the radiator where its heat energy is transferred to the atmosphere, and the cycle continues.

So as the coolant flows through the radiator, heat energy from the coolant then goes to the metal in the radiator. The cooling fan blows air through the radiator fins, allowing heat energy from the radiator to enter the air, where it goes away. Kind of like blowing on your french fries to cool them down.

Cooling fans are either belt driven or powered by an electric motor. Belt driven fans are usually equipped with a centrifugal clutch or a thermostatic clutch. A centrifugal clutch slows down the speed of the spinning fan blades as engine speed increases, by allowing the fan to freewheel, disconnected from engine torque. This is based on the assumption that if the engine speed is higher, the vehicle must be moving down the road. When the vehicle is moving, air naturally blows through the radiator, so it needs less fan speed. Cutting back on fan speed lessens load on the engine, improving fuel economy.

A thermostatic clutch has a built in bimetal spring that lessens torque to the fan blades when the engine is cold, allowing them to freewheel. When the spring heats up it allows for full fan blade operation. This too limits fan drag to improve fuel economy.

Electric cooling fans are activated by the electronic control module (ECM), using an input from the engine coolant temperature sensor. When the coolant reaches a predetermined high temperature, the ECM will turn on the fan. The ECM will turn off the fan when the coolant reaches a predetermined low temperature.

Electric fans are best because they don’t put a load on the engine, which helps to save fuel. Electronically controlling the cooling fan allows the ECM to control the temperature of the coolant, maintaining optimal coolant temperature. The ECM will also turn on the cooling fan when the air conditioner is running. The air conditioner condenser is located in front of the radiator, so it’s imperative that there is constant high speed air blowing through the radiator and the condenser when the air conditioner is running.

All automotive cooling systems are sealed with a pressure cap. Since heat increases pressure, the pressure in a cooling system starts to build as soon as the temperature rises. Needless to say, if you forget to check this pressure, it could be disastrous. Pressure caps vent the cooling system at a predetermined pressure. Most caps are set at 15 pounds per square inch (PSI) of pressure. This means that at 15 PSI the cap will vent pressure to the atmosphere. A pressure cap works using the same principle as a thermostat. The bimetal spring contracts, lifting the seal, and allowing pressure to escape.

The pressure cap can be located on either the radiator, or on a plastic degas bottle. A degas bottle is a reservoir that is placed in the engine compartment, higher up than the engine and radiator. Since air naturally rises when trapped in a liquid, any air in the cooling system will make its way to the degas bottle, and is pushed out of the pressure cap during venting. Air is detrimental to a cooling system. Trapped air will stop the flow of coolant which can cause an overheat condition, lack of passenger compartment heat, or false temperature gauge readings.

Systems that mount the pressure cap on the radiator use an overflow tank. All this tank does is catch any coolant that might escape during pressure venting. If the coolant level in the radiator should drop due to the normal ebb and flow of the cooling system, coolant will be sucked out of the overflow tank and back into the radiator.

Besides keeping your engine cool, your cooling system helps to keep you warm. The heat that blows into the passenger compartment on a cold day is transferred from the hot coolant, to the heater core, and then to the air, which is forced into the car by the blower motor.

A heater core is basically a mini radiator. Coolant flows through a series of narrow tubes that are connected by thin layers of metal, arranged in a honeycomb like configuration. The hot tubes heat the honeycomb, which transfers their heat energy to the air as it is forced through the heater core by the blower motor. This is why you often hear of a bad thermostat causing a no heat condition. If the thermostat is stuck open, the coolant doesn’t have the opportunity to reach operating temperature. Not hot coolant means not hot heat.

So this is basics of how an engine cooling system keeps the engine from self-destructing. Car engines do a real good job of concealing all of the violence that is actually going on deep inside of an internal combustion engine while it’s running. Heat is a byproduct of all that helter skelter, and your cooling system is continuously fighting the battle to keep that heat under control.