SKF self-aligning clutch release bearings are designed to control certain clutch conditions associated with the misalignment of driveline components. Evaluate the following problems that misalignment or off-centered wear of the conventional clutch release bearing can cause compared with the benefits of an SKF self-aligning clutch release bearing:

Problems of misalignment or off-centered wear:

• Rapid wear of the pressure plate fingers and release bearing face due to uneven loading.

• Release bearing noise and vibration since the rolling elements are put under extreme pressure.

• High heat and friction inside the bearing causing loss of grease resulting in premature wear and failure.

Improved performance features of the SKF self-aligning bearing:

• Immediate self-centering at initial engagement.

• Retention of centering.

• Less noise and vibration.

• Reduced wear on pressure plate fingers.

• Reduced internal bearing friction resulting in less lubrication breakdown, giving a longer service life.

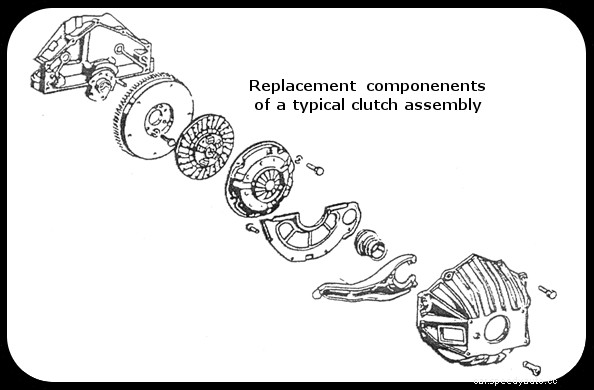

Clutch release bearing installation:

1. Disassemble the clutch assembly according to the manufacturer’s instructions.

2. Check for misalignment of parts before reassembly; check condition of clutch bearing.

3. The clutch bearing normally rides on the front bearing retainer (called the “Quill”) of the transmission. Check the quill for extreme wear and replace if damaged. Lubricate with a light amount of grease. (Note: Some bearings use a plastic insert which should not be greased.)

Worn fork damage on the back face of the clutch release bearing. Check condition of fork before reassembling. (Figure 1)

Spiral wear patterns indicate misalignment between the flywheel and the transmission input shaft. (Figure 2)

4. Lightly lubricate transmission input shaft and the pilot bearing, or the pilot on the input shaft.

5. Place the new bearing on the clutch fork and check for wear, making sure the fingers do not contact the bearing and that the fork holds the bearing carrier stationary when the bearing is rotated. Replace fork if damaged.

6. Check the fork pivot for wear and lubricate with a small amount of high temperature grease to assure smooth pivoting action.

7. Pack the groove inside the bearing carrier with grease and assemble bearing on carrier.

8. Adjust clutch free-play according to manufacturer’s specifications.

Note: Remember to check and/or replace the pilot bearing with each clutch replacement to eliminate play or vibration in the shaft.