As a general reference point, or when installing a distributor; Top Dead Center (TDC) on the compression stroke is required.

Usually it can be found by looking at timing marks; but on some engines these marks may be lost or hidden. Fortunately, there’s an easy way to discover top dead center, without the use of any timing marks.

So, being able to accurately find Top Dead Center (TDC) is a critical step; no matter what engine you are working with. There are different ways to do it; but in this article we wanted to show you a simple, quick; and practically foolproof method for finding, Top Dead Center (TDC).

Whenever you are doing a rebuild, building a new engine; or simply want to check and make sure the timing marks on your damper are still accurate.

So, if you’re relatively new to engine work and have ever pulled, or need to pull; the distributor or damper from your engine; finding Top Dead Center (TDC) on piston #1 becomes an instant priority. Finding Top Dead Center (TDC) is an essential skill for assembling and tuning engines; and is even a necessity for performing some engine diagnostic tests, such as a cylinder leak down test.

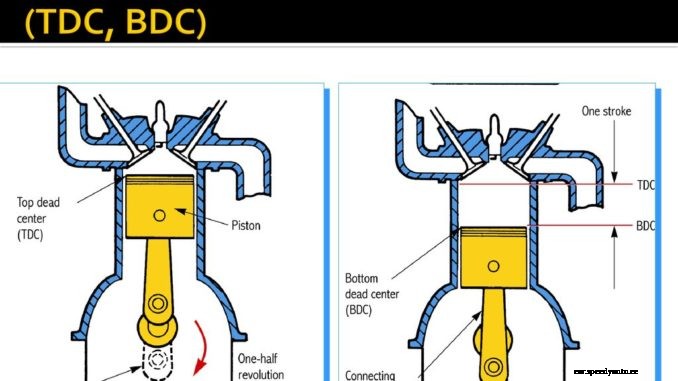

Simply put, Top Dead Center (TDC) is the position of an engine’s piston; when it is at the very top of its stroke.

Depending on whether you need to be on the compression stroke or not; there are many methods that you can use:

So, the first thing you would want to do is remove all the spark plugs. Consequently, the reason for this is, you are going to be turning the engine over by hand. Well, most likely with a wrench, on the harmonic balancer nut. This will make it a lot easier to turn.

I like to use the hose from my compression tester gauge. ( Make sure to remove the schrader valve from the hose, before you start ). Start by screwing the hose into the #1 cylinder.

To determine the location of the number one cylinder:

On a V type engine, one cylinder head is slightly forward of the other; toward the front of the engine. Cylinder number one is the forward most cylinder in that bank.

On an inline engine, the number one cylinder is located at the front of the engine; closest to the timing cover.

At this point, there are a few ways to confirm the compression stroke:

Most old school mechanics would just use the finger method. Place one finger over over the end of the hose; then rotate the crankshaft (clockwise is best, but not essential).

Use a vacuum/pressure gauge. Hook up the gauge to your hose. Again turn the engine over by hand until you see pressure.

Other things I have seen are Putting a balloon or a finger from a latex glove over the hose. The balloon or finger will fill up till it gets to (TDC) then it will suck back in.

Now remove the hose and place a long screwdriver; coat hanger or straw into the spark plug hole to feel the height of the piston.

You can turn the crankshaft back and forth (by hand ) while observing motion of the ( screwdriver; coat hanger or straw ) to get a better idea of the location of the piston. When you see it has reached its highest point of travel, it is at (TDC). It’s that easy !

Now there are times where you have to be dead on, but this covers most cases.

A more accurate way to locate (TDC) is by using a piston stop tool. Screw the tool into the #1 spark plug hole by hand; and then slowly rotate the crankshaft by hand until the piston come up against the stop.

Mark your balancer with a marker, and then slowly rotate the crankshaft by hand in the opposite direction; until you come up against the stop again.

Mark your balancer again. Measure the distance between the two marks and divide by two. As a result, This is your (TDC).

All things considered, setting an engine to top dead center, is a relatively straightforward procedure.