Most of the time, valves and piston rings, will give you warning signs, long before they actually fail.

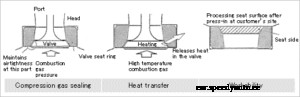

Although bad valves and piston rings have similar symptoms; the time and costs of repairing them are quite different. Valve problems, are a sign of serious issues with your engine. The intake and exhaust valves, rely on physical contact with the valve seat and guide for cooling.

So, anything that interferes with, valve cooling or creates extra heat in the valve or head; can lead to premature valve failure. Furthermore, properly sealed valves, are crucial to your engine’s compression. Problems with your engine’s piston rings often display symptoms; or signs that are similar to, other problems with low compression in a engine.

Healthy engines should have compression over, 100 psi per cylinder; with no more than 10 percent variation, between the highest and lowest readings.

Firstly, piston rings are located, between the piston and cylinder and provide, four different functions:

It is important to note that, piston rings do wear out. Therefore, you’ll have to replace them at some point.

You rarely hear about valve problems in cars nowadays. Because, modern overhead camshaft engines have, fewer components, to break down and cause problems. In the past, several components, such as non-hydraulic lifters, push-rods, springs and the valves themselves, all could go bad.

You may have heard the term “getting a valve job” because older cars, frequently needed their valves adjusted. If you have an older car, you may still have some of these problems. In contrast, modern cars valve trains, that are virtually trouble-free.

The symptoms of bad valves and piston rings are quite similar. Whenever either fails, the performance of the vehicle will drop, and other symptoms will manifest.

Let’s take a look at some warning signs, that these components are going bad:

If you notice thick smoke that’s blue-gray or light-gray; this is a good indication, your car is burning oil. It’s a sign that oil is leaking, into the combustion chamber of your engine.

Generally, the amount of blue smoke you see, with valve guide and seal failure; is fairly small and barely noticeable. If you are spewing out a large amount of smoke, then you may have more serious problems. Such as, worn valves or damaged piston rings.

As mentioned above, if the piston rings are worn out; oil will begin to leak into the combustion chamber. This causes your engine to, use up its oil supply much quicker.

When there is damage to the valves and piston rings, compression will be reduced. This causes you to lose engine power. As a result, you won’t be able to accelerate as fast, when you put your foot on the gas pedal.

Burnt valves, are another problem that contributes to power issues. Many things can cause burnt valves, but one of the most common reasons is; ignoring leaking seals and guides or failing to fix other compression problems.

Ticking noises, are the most common types of noises you will hear; when you’re having trouble with your valves. This noise gets louder and faster, as the engine is accelerated. It usually means that, some of the valve train components are, either worn or out of alignment.

Most cars have hydraulic lifters, and these lifters need, constant lubrication; with oil pressure, kept at a precise level. So, if the pressure is a little bit off, it increases play or excessive movement in the valve train.

You can do a compression test and cylinder leak down test, to help pinpoint the problem. Low compression usually indicates, that the piston rings are your problem. To further confirm worn piston rings are the problem, do a wet compression test. Here you remove the spark plug and inject a bit of oil (about a tablespoon) into the cylinder. If the compression increases, your piston rings are bad.

A cylinder leak down or cylinder leakage test, is similar to a compression test in that; it tells you how well your engine’s cylinders are sealing. But, instead of measuring pressure, it measures pressure loss.

A cylinder leak down test requires the removal, of all the spark plugs. The crankshaft is then turned, so that each piston is at top dead center (both valves closed); when each cylinder is tested. Most people start with cylinder number one and follow the engine’s firing order. A threaded coupling, attached to a leakage gauge, is screwed into a spark plug hole. Compressed air (80 to 90 psi) is then fed into the cylinder.

An engine in great condition, should generally show only 5 to 10% leakage. An engine that’s still in pretty good condition, may show up to 20% leakage. But, more than 30% leakage indicates trouble.

The neat thing about a leakage test (as opposed to a compression test) is that; it’s faster and easier to figure out where the pressure is going:

So, valves and piston rings problems, are something you should not ignore. However, they are easy to prevent, or at least delay, with proper engine maintenance. Finally, have your oil changed regularly, and fix any other engine problems promptly.