Most often, including its disassembly; regrinding of the crankshaft and replacing the engine bearings.

As long as there’s a steady flow of clean oil; an engine bearing will generally last a long time. But, if the oil’s dirty or if the supply is cut off; that’s when the problems start. That’s why, bearing lubrication is so critical. From the second the engine turns over, until it is shut down. Also, identifying the root cause of a bearing failure; is crucial in preventing a repeat failure.

Sometimes, failures are the result of, simple installation errors.

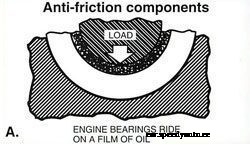

Though there is not much to an engine bearing at first glance; it is a true marvel of engineering. All bearings depend on a film of oil, to keep shafts and bearing surfaces separated:

This oil wedge, lifts the shaft off the bearing surface and supports it, during engine operations. Consequently, under normal operating conditions and a continuous supply of clean oil; the shaft and bearing surfaces, will remain separated.

The properties required for bearing materials:

Most engines have, at least two main bearings. One at each end of the crankshaft. Main bearings, support the crankshaft in the engine block. A main bearing consists of two parts. An upper and lower. The upper part of a main bearing, commonly has an oil groove, on the inner surface.

The lower of a main bearing has a hole for passing oil; to the feed holes in the crankshaft. Furthermore, some main bearings may have, thrust bearing elements; supporting axial loads and prevent movements, along the crankshaft axis.

In an engine block, crankshaft thrust bearings, are placed into grooves formed in the block’s webbing. Their purpose is to, limit the crankshaft’s forward and backward movement. As a result, keeping the crankshaft, within a specific area of motion.

Connecting rod bearings, are mounted in the, big end of the connecting rod. A bearing consists of, two parts (commonly interchangeable). Rod bearings, provide rotating motion of the crank pin; within the connecting rod.

Small end bushings provide, relative motion of the piston. Relatively to the connecting rod, joined to the piston.

Camshaft bearings, support the camshaft in the engine and allow for its rotation.

So, proper selection of bearings, will go a long way toward a successful engine rebuild. Furthermore, it is a good idea to inspect your old bearings; before starting any new rebuild or repair. Because, they do tell a story and will, help find the original problem.

So, identifying the root cause of a bearing failure; is crucial in preventing, the recurrence of the failure. A simple replacement of the bearings will not address the factors that; led up to the failure. It is important to note that, in many cases, the premature bearing failure; is due to a combination of causes. One common cause, is incorrect bearing clearance. So, if you do not find the original cause, bearing failure can repeat itself.

Because bearing manufacturers do such a great job in making bearings; they will always have the best information. We will let them speak for themselves. As their engineers, have all the information you will need. So, here is a list of the common ones we have found.

The following notes and illustrations, will assist you in the diagnosis and causes of bearing failures:

Clevite – Engine Bearings

Clevite 77 – Bearing Failure

King – Engine Bearings

Mahle – Engine Bearings

Engine bearing failure, can also occur, as a result of, faulty machining or careless assembly.

Sometimes, failures are the result of, simple installation errors:

So, your old engine bearings, can reveal a great deal about your engine. As well as, conditions that may have contributed to their failure. All bearings, will show some degree of wear. But, a close examination may reveal some scoring, wiping, dirt or; other debris embedded, in the surface of the bearings.

So, use the links above, to compare your old bearings, to the ones in the pictures. Consequently, that information may lead you to, why the original bearings failed. As a result, saving you time and money.