Shift linkage represents the connection between the gear lever and the transmission and can cause a number of issues if it’s not in good condition.

To help you solve your problem, we’re going to review the mechanics behind the shift linkage, the signs that it’s failing, and how to fix them.

Continue reading this article to find out more and save a significant sum you’d spend on professional labor!

Those of us that know a thing or two about the internal workings of the powertrain are immediately concerned whenever there’s a problem with anything transmission-related.

The truth is that most transmission problems are beyond your general mechanic and have to be handled by a professional that specializes in the field.

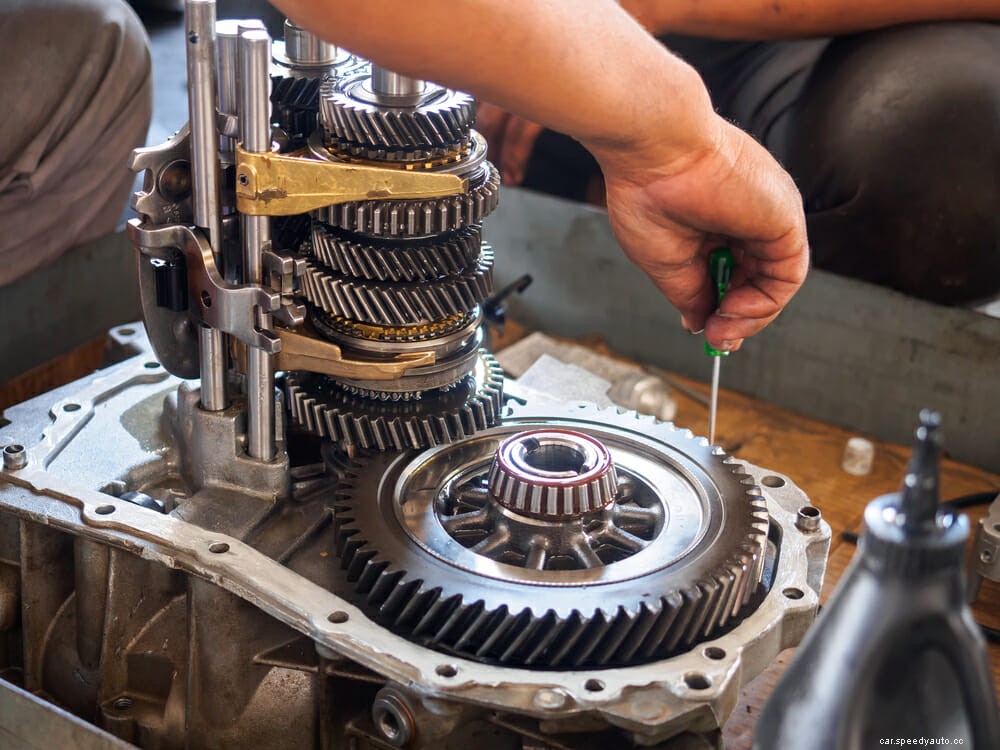

Luckily, the shift linkage is nothing more than a cable connecting the selector lever to the transmission. By pulling on the shifter, you’re mechanically switching the transmission mode from park to reverse, neutral, and different forward drive modes.

The problems with shift linkage are identifiable by the fact that even though the transmission is not responding to your commands, it’s still operating properly.

One of the most obvious signs of linkage failure are problems with moving the gear selector through all the position. As the problem progresses, it will become increasingly more difficult to shift into neutral or drive.

When the linkage collet becomes loose or the cable stretches from years of use, it’s possible that the length of travel that the cable makes between different positions isn’t enough to actually change gears on the transmission.

Changing from park to reverse will not engage the reverse gear, going into neutral might still leave the vehicle in parked gear or switch it into reverse, and so on. The point is that the currently selected gear is not synchronized with the gear transmission is in.

Some vehicles have a safety precaution where you’re not allowed to turn off the vehicle unless the gear shifter is set into parked or neutral gear.

Because linkage problems are typically accompanied by gear mismatch, the vehicle might stay in reverse when you put it in park, making it difficult to shut the engine off.

It’s rare for a vehicle to have a system that prevents you from turning off the engine, but almost all vehicles with automatic transmission won’t allow you to start the vehicle unless the gear shifter is in park or rarely neutral gear.

This symptom is the hardest to identify because everything would appear normal. You might suspect the starter or a bad fuel pump, but if you cycle the transmission through gears a few times, you might shift it back into park and start the vehicle.

There are a few failures that will cause the shift linkage problems, but the two we can work on at home are the cable length and repairing the linkage collet.

The process of adjusting the length of the shift linkage cable is simple but also quite delicate. You’ll need to elevate the vehicle safely and have a helper shift gears while you’re adjusting them from underneath.

Tools you’ll need

| Title | Price | Buy | |

|---|---|---|---|

Top

Top | Pro-Lift F-767 Grey Low Profile Floor Jack - 2 Ton Capacity | ||

Top

Top | Pro-LifT T-6903D Double Pin Jack Stand - 3 Ton, 1 Pack | ||

Top

Top | MAXXHAUL 70472 Solid Rubber Heavy Duty Black Wheel Chock 2-Pack, 8" x 4" x 6" | ||

Top

Top | Stalwart 75-HT3009 Combo SAE & Metric Wrench Set with Carry Case, 22 Piece |

Step by step guide

The following video has more information than you need, but it does a great job of giving you a visual representation of what’s happening when you pull on the gear selector lever.

The video above shows a fairly basic shift linkage that doesn’t have a large collet and heavy-duty cable shrouding. The collet (bushing) sits between the cable and the transmission bracket, and when it brakes, it will create enough of a distance for the gears to not synchronize, or it might even cause the cable to come off and not shift at all.

You can’t simply buy a new collet and replace it, as most stores sell it in a complete shift linkage kit that costs hundreds of dollars. Instead, we’re going to make our own with basic tools and materials.

Tools you’ll need

| Title | Price | Buy | |

|---|---|---|---|

Top

Top | Pro-LifT F-2315PE Grey Hydraulic Trolley Jack Car Lift with Blow Molded Case-3000 LBS Capacity | ||

Top

Top | Amazon Basics Steel Jack Auto Stands, 3 Ton Capacity, 1 Pair | ||

Top

Top | MAXXHAUL 70472 Solid Rubber Heavy Duty Black Wheel Chock 2-Pack, 8" x 4" x 6" | ||

Top

Top | Dorman 31016 Shock Absorber Bushing, Pack of 2 | ||

Top

Top | Medpride Disposable Scalpel Blades| #10 Sharp, Tempered Stainless-Steel Blades | Pack of 10 Sterile Scalpel Knives| Plastic Handle| Individual Pouches| for Dermaplaining, Podiatry, Crafts & More | ||

Top

Top | 304 Stainless Steel Flat Washers Set 580 Pieces, 9 Sizes - M2 M2.5 M3 M4 M5 M6 M8 M10 M12 Suitable for Home Decoration, Factories Repair, Kitchens, Shops and Outdoor Construction | ||

Top

Top | Lucas Oil Red"N" Tacky Grease, 1 Pound Tub, 16 Ounces (LUC10574) | ||

Top

Top | Hilitchi 300-Pcs Alloy Steel E-Clip Circlip External Retaining Ring Assortment Set - 1.5mm to 10mm |

Step by step guide

If you’re having problems with shifting gears because of the shift linkage, the problem can be solved by either adjusting it or replacing the assembly. The transmission itself can only be worked on by an experienced professional.

Yes, the automatic transmission has a shift linkage that connects the gear shift lever to the bracket located on the housing of the transmission. It allows the driver to control the mode in which the transmission is operating.

Repairing shift linkage is not a major task, so the cost of labor is relatively low, $50-100 on average. The cost of the shift linkage itself ranges from $50 to $200.

A bad shift solenoid will have a number of symptoms: check engine light, transmission warning light delayed or skipped gears, and general shifting problems.

The gear shift lever is connected to the transmission by a cable called shift linkage. High mileage and aggressive shifting will cause the collet bushing to break and the cable to extend. When this happens, the shifter will not have a responsive connection to the transmission.

The bushing between the shifter linkage and the transmission bracket isn’t expensive on its own – $10 on average. However, the problem is finding a bushing that fits, as most are not sold individually and instead are packaged with the entire shift linkage kit.

Repairing the shift linkage is a simple task that requires a bit of finesse and patience to get right. Getting the tension of the cable right will require some trial and error, but if you work slowly and test all the gears while monitoring the transmission bracket, you’ll get it working properly in no time!

View other related VehicleFreak posts here:

What Does “L” Mean on a Car’s Gear Shift?

Why Does My Transmission Shift Hard From 1st To 2nd?

How To Test Transfer Case Shift Motor