Last year, when GM disclosed that they are paying $145 per kWh for LG Chem battery cells many people were surprised. In fact, LG Chem got uncomfortable with the disclosure and promptly announced that this kWh price was exclusive and part of a broader package, since LG Chem supplies almost every electronics inside the the Chevrolet Bolt EV…

However, now according to some sources, LG Chem is available to offer Volkswagen a better deal, by supplying just the battery cells for roughly $140 per kWh.

While – for the moment – LG Chem doesn’t confirm the information, it seems that the South Korean company is in better position than its Chinese contender CATL (Contemporary Amperex Technology Ltd) to secure the battery deal.

It’s important to acknowledge that Volkswagen already has government approval in China for a new joint venture with Anhui Jianghuai Automobile Group (JAC Motor) to build electric cars and needs a battery cell supplier.

To further debunk the battery high price myth that makes electric cars inevitably expensive, Sam Jaffe, Managing Director of Cairn Energy Research Advisors confirmed on the Benchmark World Tour 2017 in New York that battery cells price is already under $140 per kWh.

To destroy the battery high price myth – that makes electric cars inevitably expensive – was the main reason why I decided to create this blog, especially since even some websites dedicated to electric cars still reinforce it.

In 2017, there is no reason for the Hyundai IONIQ Electric – with its 28 kWh battery – to roughly cost 10.000 € more than the much complex hybrid version for example, as the former Toyota chief designer Satoshi Ogiso admitted.

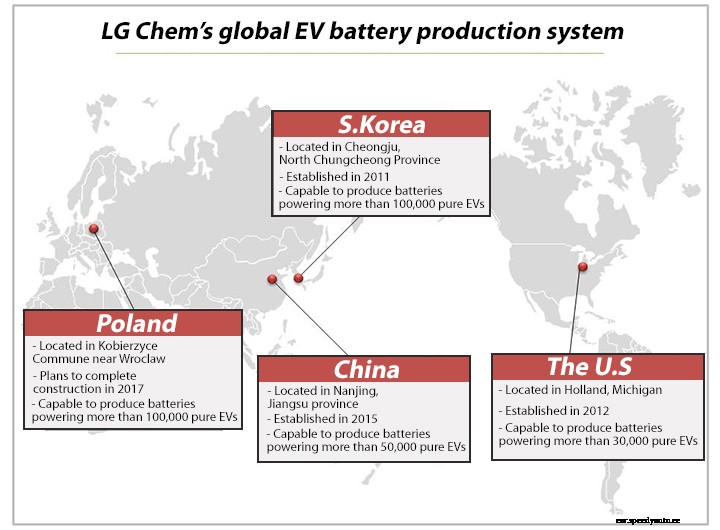

To finalize, I have to say that I’m very optimistic for the coming months regarding electric cars. I expect an increase of production and prices coming down – slowly but steady. Especially because the South Korean battery cell makers’ problems with the Chinese Government seem to be sorted and the European battery cell plants from LG Chem and Samsung SDI are close to start production.

I have reasons to believe that while the 2018 Nissan Leaf is expected to debut with AESC battery cells, later next year with four LG Chem battery cell plants operating at full speed around the world, LG Chem will finally have the production capacity needed to supply battery cells for the Nissan Leaf. So don’t be surprised to see the 2019 Nissan Leaf with two LG Chem battery options (probably around 48 and 60 kWh).

LG Chem EV battery global production

I think that the only reason why the 2018 Nissan Leaf won’t arrive with LG Chem battery cells from the beginning is because Nissan is already behind competition and couldn’t wait another year to show improvements. In fact, Nissan is already one year behind schedule, since an improved Nissan Leaf with more range was expected for November last year in its 2017 MY and was postponed multiple times.

As a side note, I wonder what deal will LG Chem offer to Nissan – probably around $130/kWh -, but also wonder what the Hyundai IONIQ Electric’s price will be when Hyundai finally increase the monthly production to 4.000 units.

What about you? What are your expectations regarding the electric car’s evolution now that battery cell production is about to increase exponentially around the world?! Furthermore, will South Korean battery cell makers expand production to Panasonic/Tesla Gigafactory levels anytime soon? I wouldn’t bet against it…